Choosing the wrong carbon fiber can increase costs by 40% and cause project failure. This carbon fiber selection guide reveals how aerospace, automotive & robotics engineers select optimal materials .

1. Understanding Carbon Fiber Fundamentals

Key Properties:

- High Strength-to-Weight Ratio (5x stronger than steel at 1/4 the weight)

- High Stiffness-to-Weight Ratio

- Low Thermal Expansion

- Excellent Fatigue Resistance

- Corrosion Resistance

- Electrical Conductivity

- Anisotropic: Properties vary with fiber direction.

2. Critical Selection Parameters

• Unidirectional (UD): Fibers all in 0°. Max strength/stiffness in primary direction. Laminates.

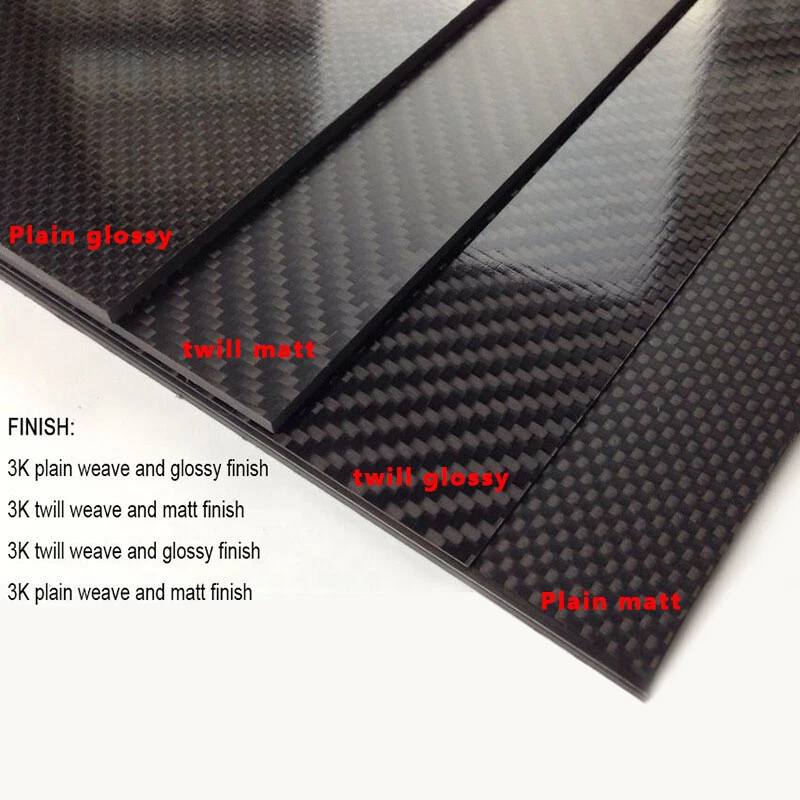

• Plain Weave: Simple over/under. Good stability, balanced properties. Easiest handling.

• Twill Weave (2×2, 4×4): Smoother drape, better conformability than plain. Complex contours.

• Satin Weave (e.g., 5HS, 8HS): Excellent drape, reduced crimp. Complex molds, high-quality surfaces.

• Non-Crimp Fabric (NCF): Stitched layers of UD or woven plies. Higher mechanical performance.

- Small Tow (1K-12K):

- Better drape, surface finish. Complex shapes, sports goods.

- Large Tow (24K-50K+):

- Lower cost per kg, higher deposition rates. Automotive, industrial.

• Unidirectional (UD): Fibers all in 0°. Max strength/stiffness in primary direction. Laminates.

• Plain Weave: Simple over/under. Good stability, balanced properties. Easiest handling.

• Twill Weave (2×2, 4×4): Smoother drape, better conformability than plain. Complex contours.

• Satin Weave (e.g., 5HS, 8HS): Excellent drape, reduced crimp. Complex molds, high-quality surfaces.

• Non-Crimp Fabric (NCF): Stitched layers of UD or woven plies. Higher mechanical performance.

some common weaves

Weight per unit area (g/m² or oz/yd²). Affects laminate thickness, resin content, process time.

Ensure compatibility with chosen resin system (Epoxy, Polyester, Vinyl Ester, Bismaleimide, Thermoplastic).

Critical for fiber-matrix adhesion (bond strength). Specify based on resin type.

• Dry Fabric: Requires resin infusion.

• Prepreg: Pre-impregnated with resin (frozen storage). Consistent quality, easier layup.

• Chopped Strand/Mat: For molding compounds, short fiber reinforcement.

• Pultruded Profiles: Constant cross-sections (rods, tubes).

3. Application-Based Recommendations

- Aerospace (Primary Structures): IM or HM fibers, Thin-ply UD or woven prepregs, High resin content control.

- Automotive (Performance): SM or IM fibers, Large tow fabrics or NCF, Fast-cure prepregs/resin systems.

- Sporting Goods (Bikes, Rackets): SM or IM fibers, 3K twill weaves for aesthetics, UD for performance zones, Prepreg or wet layup.

- Consumer Electronics: HM fibers for stiffness, Thin weaves or UD for sleek profiles, EMI shielding grades.

- Industrial/Robotics: SM or IM fibers, Cost-effective large tow fabrics, Epoxy or vinyl ester resins.

- Marine: SM fibers, Woven fabrics (twill/satin), Vinylester or epoxy for corrosion resistance.

4. Supplier & Quality Considerations

- Supplier Reputation: Certifications (AS9100, ISO 9001), Aerospace heritage.

- Consistency: Batch-to-batch variability in properties, sizing, weight.

- Data Availability: Access to certified mechanical property data (tensile, compressive, shear).

- Lead Times & Availability: Critical for project planning.

5. Processing Considerations

- Manual Layup (Wet): Choose fabrics with good drape (twill, satin), manageable areal weight.

- Resin Infusion (VARTM, RTM): Select permeable fabrics/NCFs, compatible flow media.

- Prepreg Layup: Requires autoclave/oven cure. Consider tack, out-life, cure cycle.

- Compression Molding: Chopped fiber, SMC, or preformed fabrics.

- Automated Processes (ATL/AFP): UD tapes or slit fabrics. Precision width control.

6. Cost Optimization

-

Evaluate: Large tow vs. small tow, Dry fabric vs. prepreg, Standard modulus vs. high modulus.

-

Minimize Waste: Efficient nesting, optimal cutting methods.

-

Process Efficiency: Faster cure resins, reduced labor techniques (automation, infusion).

7. Key Decision Flowchart

- Define Application Requirements: Loads (tension, compression, shear), stiffness, weight targets, environment, safety factors.

- Identify Critical Properties: Is strength, stiffness, impact resistance, or fatigue life paramount?

- Consider Manufacturing Method: Wet layup, prepreg, infusion, molding?

- Select Fiber Type & Tow Size: SM, IM, HM? 3K, 12K, 50K?

- Choose Weave & Areal Weight: UD, plain, twill, satin? What g/m²?

- Specify Resin Compatibility & Form: Prepreg or dry fabric? Compatible resin system.

- Evaluate Suppliers & Cost: Balance performance, quality, and budget.

- Prototype & Test: Validate selection before full-scale production.

8. Important Notes

- Consult Experts: Engage material scientists or composite engineers early.

- Test: Material data sheets are guides; perform application-specific testing.

- Consider the Entire System: Fiber is only one component. Resin, core (if sandwich), and manufacturing process are equally critical.

- Sustainability: Explore recycled carbon fiber options where performance allows.

Still confused ? Contact Us Here