الأسئلة الشائعة

في شركة E-YOUNG Composites، نحن متخصصون في تصنيع منتجات ألياف الكربون عالية الجودة والمخصصة والمصممة خصيصاً لتلبية متطلباتك الفريدة. لضمان عملية طلب سلسة وفعالة، اتبع الخطوات التالية:

حتى 1 متر

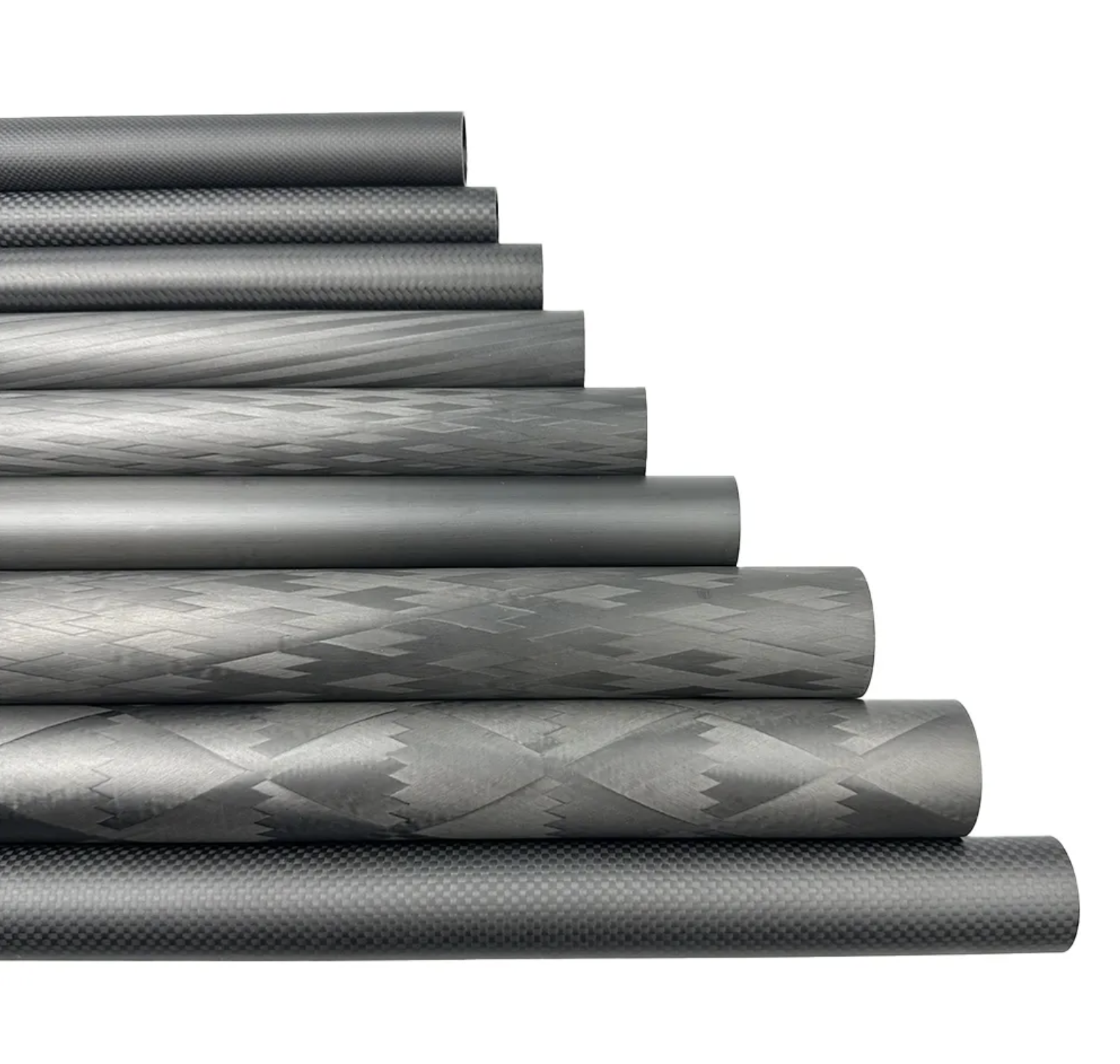

إليك مقارنة مفصلة بين أنابيب مدرفلة من ألياف الكربون و أنابيب ذات جرح خيطي باللغة الإنجليزية، وتغطي عمليات التصنيع والأداء والتطبيقات وغيرها:

عملية التصنيع

| أسبكت | أنابيب ملفوفة | أنابيب الجرح الشريطي |

|---|---|---|

| العملية الأساسية | التفاف طبقات من النسيج المسبق التجهيز أو النسيج الجاف حول مغزل، متبوعًا بالمعالجة. | اللف الآلي للألياف المشبعة بالراتنج على مغزل بزوايا مضبوطة (على سبيل المثال، 0 درجة، ±45 درجة، 90 درجة)، ثم معالجتها. |

| الأتمتة | إعداد يدوي أو شبه آلي وبسيط. | مؤتمتة للغاية، وتتطلب معدات دقيقة للتحكم في شد الألياف وزاوية الألياف. |

| اتجاه الألياف | تقتصر على الاتجاهات المحورية أو الطوقية. | محاذاة ألياف متعددة الزوايا لتحسين القوة والصلابة. |

| مرونة الشكل | الأفضل للأشكال الأسطوانية البسيطة. | مناسبة للأشكال الهندسية المعقدة (مثل المقاطع العرضية المدببة وغير المنتظمة). |

مقارنة الأداء

| الممتلكات | أنابيب ملفوفة | أنابيب الجرح الشريطي |

|---|---|---|

| القوة الميكانيكية | قوة محورية عالية ولكن قوة طوقية ضعيفة؛ عرضة للتفكيك. | قوة محورية/طوقية متوازنة؛ مقاومة انضغاطية/التوائية فائقة. |

| تباين الخواص | متباين الخواص بدرجة كبيرة (يعتمد على الاتجاه). | تقليل تباين الخواص عبر طبقات متعددة الزوايا. |

| كفاءة الوزن | معتدل (سمك الجدار غير متساوٍ). | ممتاز (توزيع موحد للألياف، تحكم دقيق في سمك الجدار). |

| مقاومة التعب والإجهاد | أقل (ترابط بيني ضعيف بين الطبقات). | عالية (ألياف متصلة، التصاق قوي بين الطبقات). |

التكلفة والإنتاج

| العامل | أنابيب ملفوفة | أنابيب الجرح الشريطي |

|---|---|---|

| تكلفة المعدات | منخفضة (أدوات بسيطة أو يدوية). | عالية (ماكينات اللف المتخصصة، وأنظمة الشد). |

| تكلفة الإنتاج | منخفضة للدفعات الصغيرة. | تكلفة أولية عالية، ولكنها فعالة من حيث التكلفة بالنسبة للكميات الكبيرة. |

| سرعة الإنتاج | سريع (عملية معالجة بسيطة). | أبطأ (اللف الدقيق والمعالجة). |

| قابلية التوسع | يقتصر على الإنتاج على نطاق صغير. | مثالية للإنتاج بكميات كبيرة. |

التطبيقات

| الحقل | أنابيب ملفوفة | أنابيب الجرح الشريطي |

|---|---|---|

| صناعي | أجزاء زخرفية وإطارات خفيفة الوزن وأذرع طائرة بدون طيار. | خزانات الضغط العالي وخطوط الأنابيب والأذرع الآلية. |

| الطيران والفضاء | المكونات غير الحاملة (مثل الأقواس الداخلية). | أغلفة محركات الصواريخ، ومعدات هبوط الطائرات. |

| معدات رياضية | قضبان الصيد منخفضة التكلفة وأعمدة الخيام. | إطارات الدراجات الراقية وصواري اليخوت. |

| الطاقة | — | صهاريج تخزين الهيدروجين، وأنابيب صاري التوربينات الهوائية. |

دليل الاختيار

- اختر الأنابيب الملفوفة:

- قيود الميزانية.

- التخصيص منخفض الحجم.

- التطبيقات الإنشائية غير الحرجة (على سبيل المثال، الجماليات والإطارات خفيفة الوزن).

- اختر أنابيب الجرح الشريطي:

- تطبيقات حاملة الأحمال عالية الأداء.

- متطلبات توجيه الألياف المعقدة.

- إنتاج ضخم مع رقابة صارمة على الجودة.

يمكن تصنيع أحجام مخصصة تصل إلى 354 بوصة × 118 بوصة × 2 بوصة. يُرجى الاتصال بنا لمزيد من التفاصيل

حتى 230 درجة مئوية (446 درجة فهرنهايت)

نستخدم ألياف الكربون من Toray. تمثل ألياف الكربون T300 وT700 وT800 من Toray مجموعة من المواد عالية الأداء المصممة خصيصًا لتلبية الاحتياجات المختلفة. تُعد T300 خياراً فعالاً من حيث التكلفة للأغراض العامة، بينما توفر ألياف T700 قوة أعلى للتطبيقات الأكثر تطلباً. وتُعد ألياف T800، بفضل قوتها ومعاملها الفائقين، مثالية للاستخدامات الفضائية والصناعية المتقدمة. تُعرف ألياف الكربون هذه على نطاق واسع بموثوقيتها وتعدد استخداماتها في مختلف الصناعات

| T300 | T700 | T800 | |

|---|---|---|---|

| قوة الشد | 3,530 ميجا باسكال | 4,900 ميجا باسكال | 5,880 ميجا باسكال |

| معامل الشد | 230 جيجا باسكال | 230 جيجا باسكال | 294 جيجا باسكال |

| الاستطالة | 1.5% | 2.1% | 2.0% |

| الكثافة | 1.76 جم/سم مكعب | 1.80 جم/سم مكعب | 1.81 جم/سم مكعب |

| التطبيقات | الأغراض العامة | عالية القوة | أداء فائق الأداء |