Carbon fiber sandwich panels are renowned for their exceptional strength-to-weight ratio and rigidity. By combining thin carbon fiber skins with a lightweight core material like foam or honeycomb, these panels achieve performance characteristics that solid materials cannot match. However, a common and often overlooked compromise is the unfinished, exposed core on the panel edges. This not only looks unprofessional but can also compromise the panel’s long-term durability.

At E-YOUNG Composites, we believe a product isn’t truly finished until every detail is perfected. That’s why we offer professional carbon fiber sandwich panel edge banding – a meticulous process that elevates your components from simply functional to truly exceptional.

What is Carbon Fiber Edge Banding?

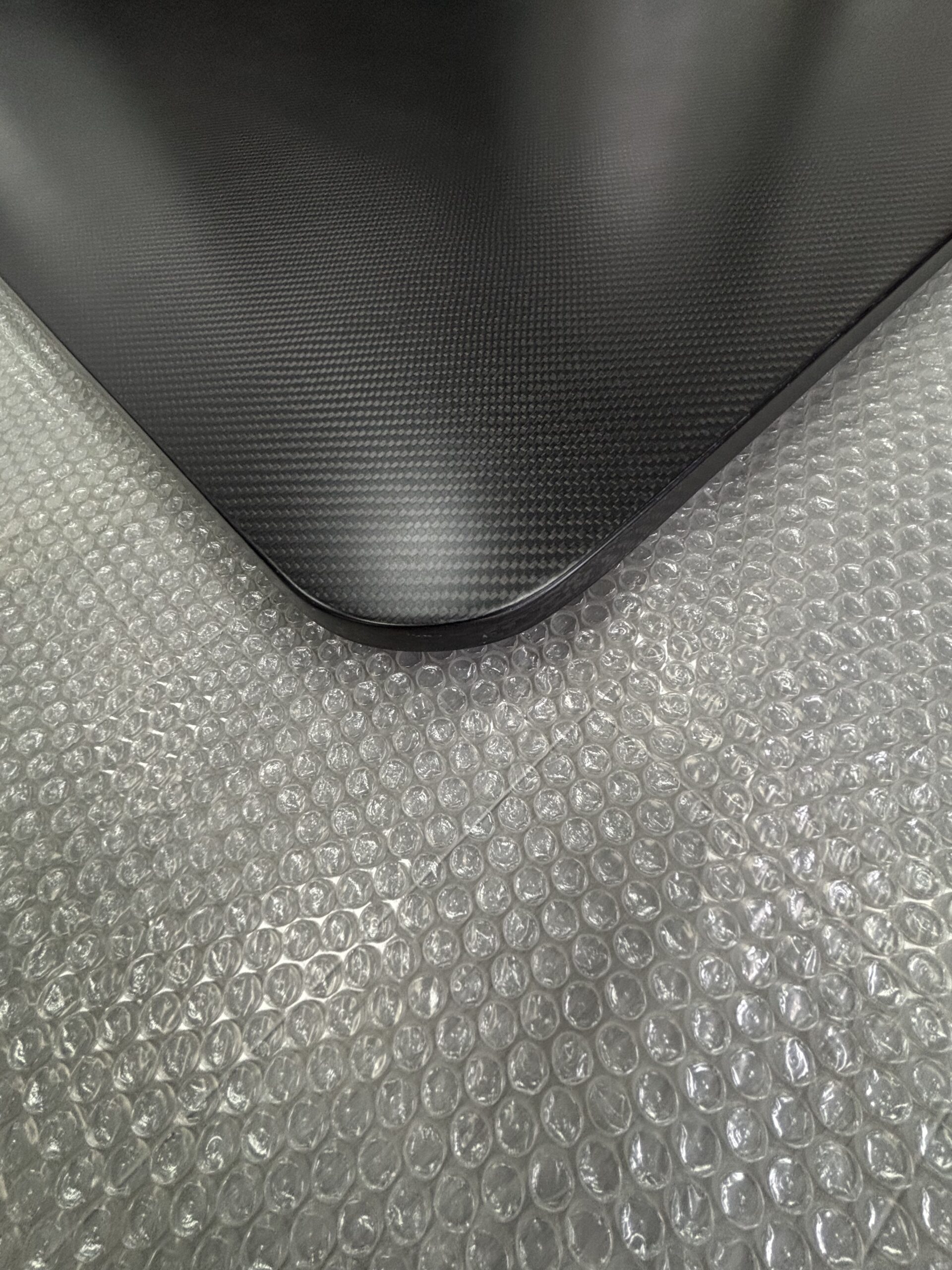

Edge banding is a post-processing technique where the exposed side of a sandwich panel is fully encapsulated with a precisely fitted strip of carbon fiber laminate. This process seamlessly integrates with the panel’s top and bottom skins, creating a continuous, all-carbon fiber surface.

In simple terms, we use custom-formed carbon fiber parts to “wrap” the edges, completely covering the core material. This results in a monolithic, clean, and visually stunning black edge that matches the finish of the panel faces.

Key Benefits of Professional Edge Banding

Why should you specify edge-banded panels for your project? The advantages are significant:

-

Aesthetic Superiority: The most immediate benefit is the visual upgrade. A clean, sealed edge provides a seamless, high-end, and professional appearance that is critical for consumer-facing products in industries like automotive, aerospace, and luxury goods. It signals quality and attention to detail.

-

Enhanced Durability and Protection: An exposed core is a weak point. It can be susceptible to moisture ingress, leading to core degradation or delamination. It can also be damaged from impact or exposure to chemicals. Edge banding acts as a protective barrier, shielding the core and significantly extending the panel’s lifespan.

-

Improved Structural Integrity: The added carbon fiber laminate along the edge can increase the overall torsional stiffness and impact resistance of the panel. By fully encapsulating the core, we create a more robust and reliable component.

-

Simplified Integration: A smooth, finished edge is easier to handle and integrate into assemblies without worrying about snagging or damaging the core material.

Our Precision Edge Banding Process

Many manufacturers see edge banding as an optional extra. At E-YOUNG, we see it as an integral part of delivering a superior product. Our process is designed for perfection:

-

Precision Machining: The panel edges are first precision-cut and machined to ensure a perfectly flat and clean surface for the laminate to adhere to.

-

Custom Laminate Layup: We create custom carbon fiber laminates that match the thickness and curvature of your specific panel.

-

Expert Bonding: Using high-performance aerospace-grade adhesives and precise vacuum-bagging techniques, we bond the carbon fiber edge piece to the panel. This ensures a void-free bond with maximum strength.

-

Curing and Finishing: The assembly is cured under controlled conditions. Once complete, the edge is sanded and clear-coated alongside the panel faces, resulting in a flawless, seamless finish that looks as if it were molded in one piece.

Ready to Elevate Your Composite Projects?

Don’t let unfinished edges undermine the quality of your high-performance components. The small additional investment in professional edge banding from E-YOUNG Composites pays dividends in product quality, customer perception, and long-term reliability.

Contact us today to discuss your project requirements. Let us show you how our expertise in carbon fiber and glass fiber composites can deliver the perfect finish for your products.

📧 Email us for a custom quote: info@carbonfibercfk.com