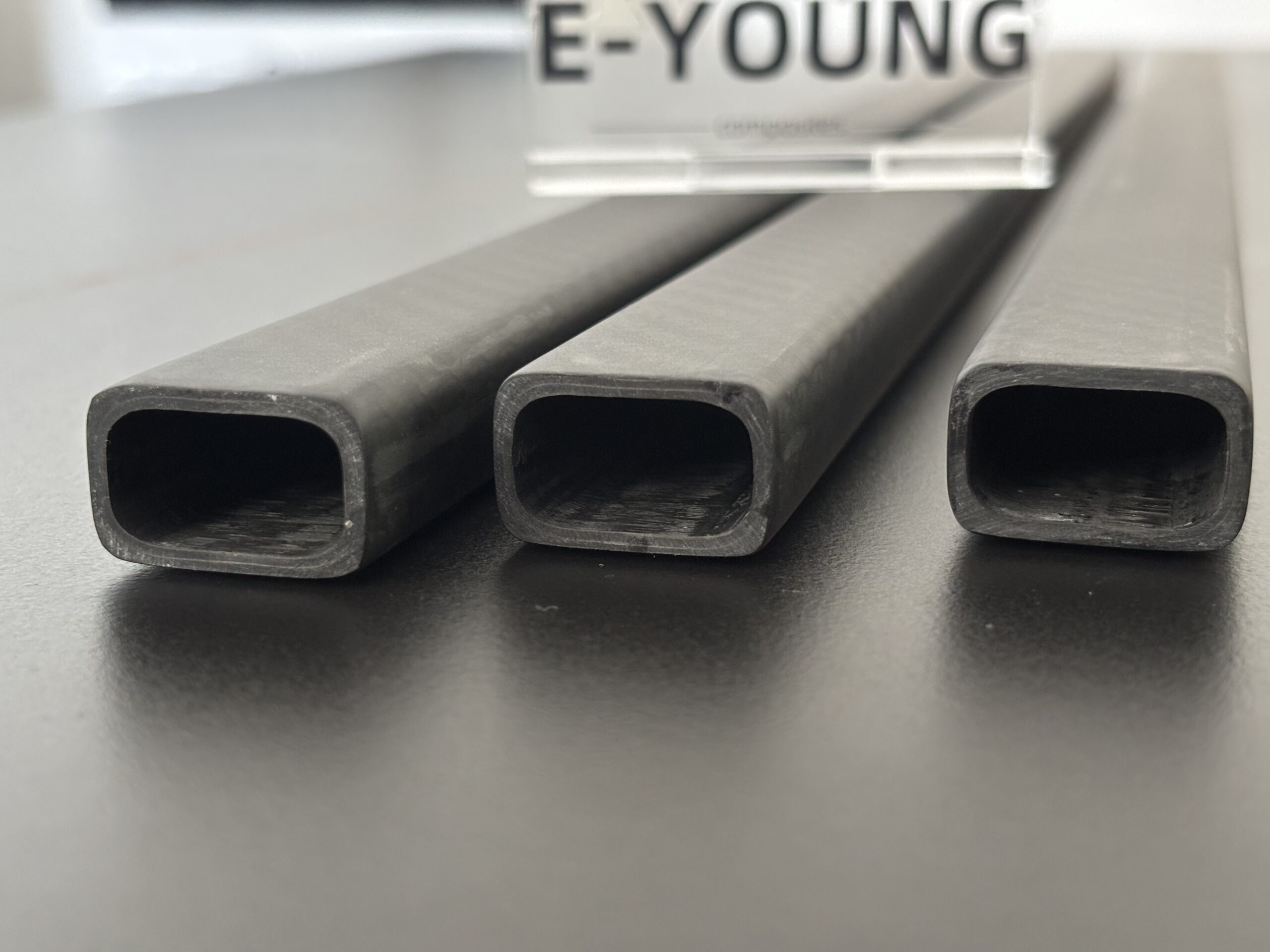

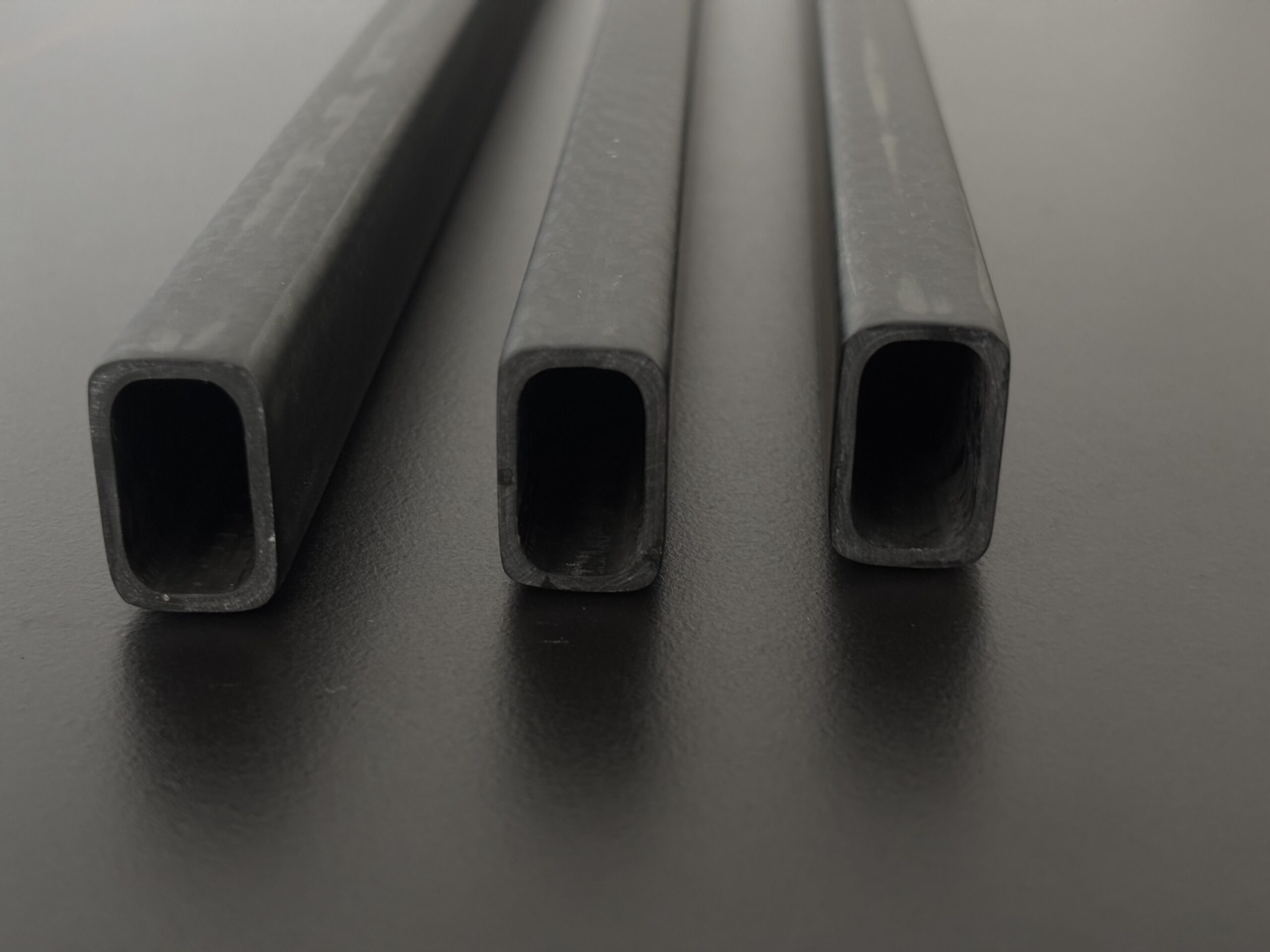

E-YOUNG Composites ist ein führender Hersteller von kundenspezifischen Hochleistungs-Rechteckrohren aus Kohlefaser. Unsere Rohre wurden für Anwendungen entwickelt, bei denen ein hervorragendes Verhältnis von Steifigkeit zu Gewicht, außergewöhnliche Haltbarkeit und Designflexibilität von größter Bedeutung sind, und übertreffen herkömmliche Metalllösungen. Unter Verwendung fortschrittlicher Formpressverfahren und hochwertiger Rohstoffe liefern wir kundenspezifische Profile, die Ihre genauen Spezifikationen für Größe, Wandstärke und mechanische Eigenschaften erfüllen.

Warum sollten Sie sich für unsere kundenspezifischen Rechteckrohre aus Kohlefaser entscheiden?

-

Unerreichte Festigkeit und geringes Gewicht: Erleben Sie eine erhebliche Gewichtsreduzierung ohne Beeinträchtigung der strukturellen Integrität. Unsere Kohlefaserrohre bieten eine außergewöhnliche Festigkeit und Steifigkeit, die die von Stahl oder Aluminium bei einem Bruchteil des Gewichts weit übertrifft.

-

Präzisionsformpressen: Unser spezialisiertes Formpressen Verfahren gewährleistet eine gleichmäßige Faserausrichtung, einen hohen Faservolumengehalt und eine hervorragende Oberflächengüte auf allen vier Seiten. Dies führt zu einer überragenden Maßgenauigkeit und mechanischen Leistung in jedem Rohr.

-

Vollständige Anpassung: Ihr Design, unser Know-how. Wir glauben nicht an die Einheitsgröße. Wir fertigen Rohre nach Ihren genauen Anforderungen für Außenabmessungen, Innenabmessungen, Wandstärke und Länge. Sagen Sie uns, was Sie brauchen, und wir fertigen es an.

-

Hochwertige Rohstoffe: Wir verwenden nur Hochwertige Kohlefasergewebe und Epoxidharzsysteme von zuverlässigen Lieferanten. Diese Verpflichtung zur Qualität garantiert ein Endprodukt mit optimalen Leistungsmerkmalen und langfristiger Zuverlässigkeit.

-

Bewährte Leistung in anspruchsvollen Anwendungen: Von Sportgeräten bis hin zur industriellen Automatisierung vertrauen Ingenieure und Konstrukteure weltweit bei kritischen Anwendungen auf unsere Rohre.

Anwendungen unserer Carbonfaser-Rechteckrohre

Unsere kundenspezifischen Rechteckrohre sind vielseitige Komponenten, die in verschiedenen Branchen eingesetzt werden:

-

Sport und Freizeit: Perfekt für Hochleistung Eishockeyschläger-Schäfte, Bogenschießen, UAV/Drohnenrahmen und Kajakpaddel, bei denen leichte Steifigkeit für Geschwindigkeit und Kontrolle entscheidend ist.

-

Luft- und Raumfahrt & UAV/Drohnen: Unverzichtbar für die Herstellung von leichten Flugzeugzellen, Trägern und Strukturelementen, die das Gesamtgewicht reduzieren und die Nutzlast oder Flugzeit erhöhen.

-

Robotik und Automatisierung: Ideal für Roboterarme, Portale und Rahmenkonstruktionen, bei denen eine geringe Masse die Trägheit minimiert und so schnellere Bewegungen und höhere Präzision ermöglicht.

-

Industrie und Automobil: Wird in Vorrichtungen, Schutzrahmen und für Innenraumkomponenten in hochwertigen Automobilanwendungen verwendet.

-

Medizinische und wissenschaftliche Ausrüstung: Bietet einen stabilen, leichten und unmagnetischen Rahmen für medizinische Geräte und Laborausrüstung.

Unser Herstellungsprozess: Formpressen

Bei E-YOUNG Composites sind wir spezialisiert auf Formpressen zur Herstellung von Kohlefaser-Rechteckrohren. Bei diesem fortschrittlichen Verfahren werden präzise zugeschnittene Stapel von hochwertigem Kohlefaser-Prepreg in eine angepasste Metallform eingelegt. Unter kontrollierter Hitze und hohem Druck wird das Material zu einem dichten, hohlraumfreien Verbundteil ausgehärtet.

Vorteile dieser Methode für rechteckige Rohre:

-

Ausgezeichnete Formbeständigkeit: Produziert Rohre mit scharfen, gleichmäßigen Ecken und gleichmäßiger Wandstärke.

-

Hervorragende Oberflächengüte: Hinterlässt eine glatte, lackierfertige Oberfläche auf allen Oberflächen, direkt aus der Form.

-

Hohe strukturelle Integrität: Erzeugt Teile mit außergewöhnlicher Festigkeit und Konsistenz, Charge für Charge.

Vertrauen bei Branchenführern

“E-YOUNG Composites belieferte uns mit maßgeschneiderten rechteckigen Carbonrohren für unsere neueste Linie von Hochleistungs-Eishockeyschlägern. Die Konsistenz, das Finish und die Steifigkeit der Rohre waren genau das, was wir brauchten, um unseren Spielern einen Wettbewerbsvorteil zu verschaffen.”

- Führender Hersteller von Eishockey-Ausrüstung

Fordern Sie noch heute Ihr kostenloses Angebot an

Sind Sie bereit, kundenspezifische Hochleistungs-Rechteckrohre aus Kohlefaser in Ihr Produkt zu integrieren? Das E-YOUNG-Team ist hier, um Ihre Konzepte in die Realität umzusetzen.

Kontaktieren Sie uns noch heute, um Ihre Projektanforderungen zu besprechen. Schicken Sie uns einfach Ihre gewünschten Abmessungen, den Jahresverbrauch und die Anwendung, und wir werden Ihnen ein wettbewerbsfähiges Angebot und technische Unterstützung anbieten.

E-Mail: info@carbonfibercfk.com