rollenumwickelte Kohlefaserrohre

E-YOUNG Composites ist ein führender Hersteller von hochwertigen rollenumwickelten Kohlefaserrohren. Wir sind spezialisiert auf kundenspezifische Lösungen für Branchen, in denen Festigkeit, Steifigkeit und Gewichtsreduzierung entscheidend sind.

kontaktieren Sie uns unter https://carbonfibercfk.com/contact-us/ oder per E-Mail info@carbonfibercfk.com

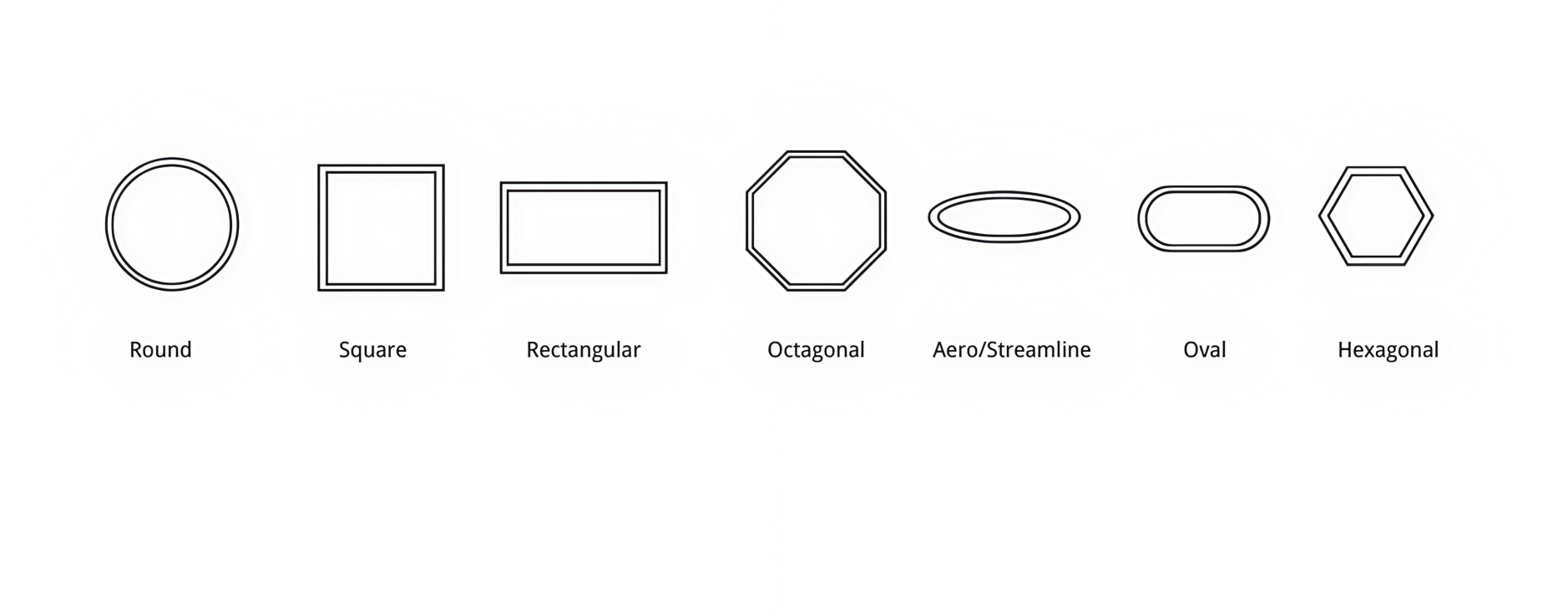

Verfügbare Röhrenformen

Verfügbare Arten von Kohlenstofffasern

| Eigenschaften | T300 | T700 | T800 |

|---|---|---|---|

| Dichte (g/cm³) | 1.55 | 1.55 | 1.55 |

| Zugfestigkeit (MPa) | 3400 | 4900 | 5200 |

| Elastizitätsmodul (GPa) | 240 | 250 | 295 |

| Dehnung (%) | 1.78 | 1.76 | 1.7 |

Verfügbare Epoxidharze

- Herkömmliches Epoxidharz

- Hitzebeständiges Epoxidharz。 Bis zu 230°C (446°F)

Prüfen Sie, wie unsere Rohre sind

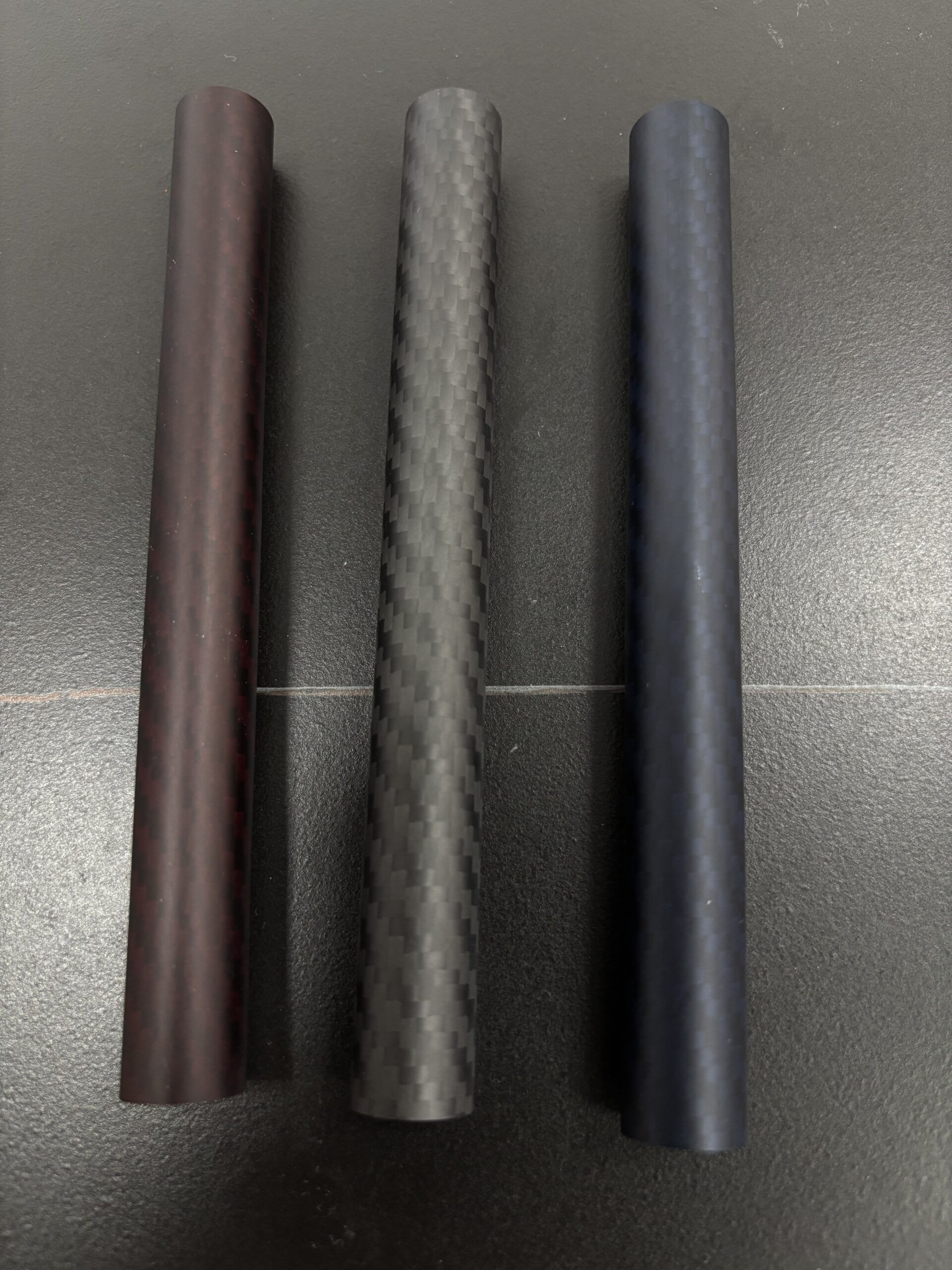

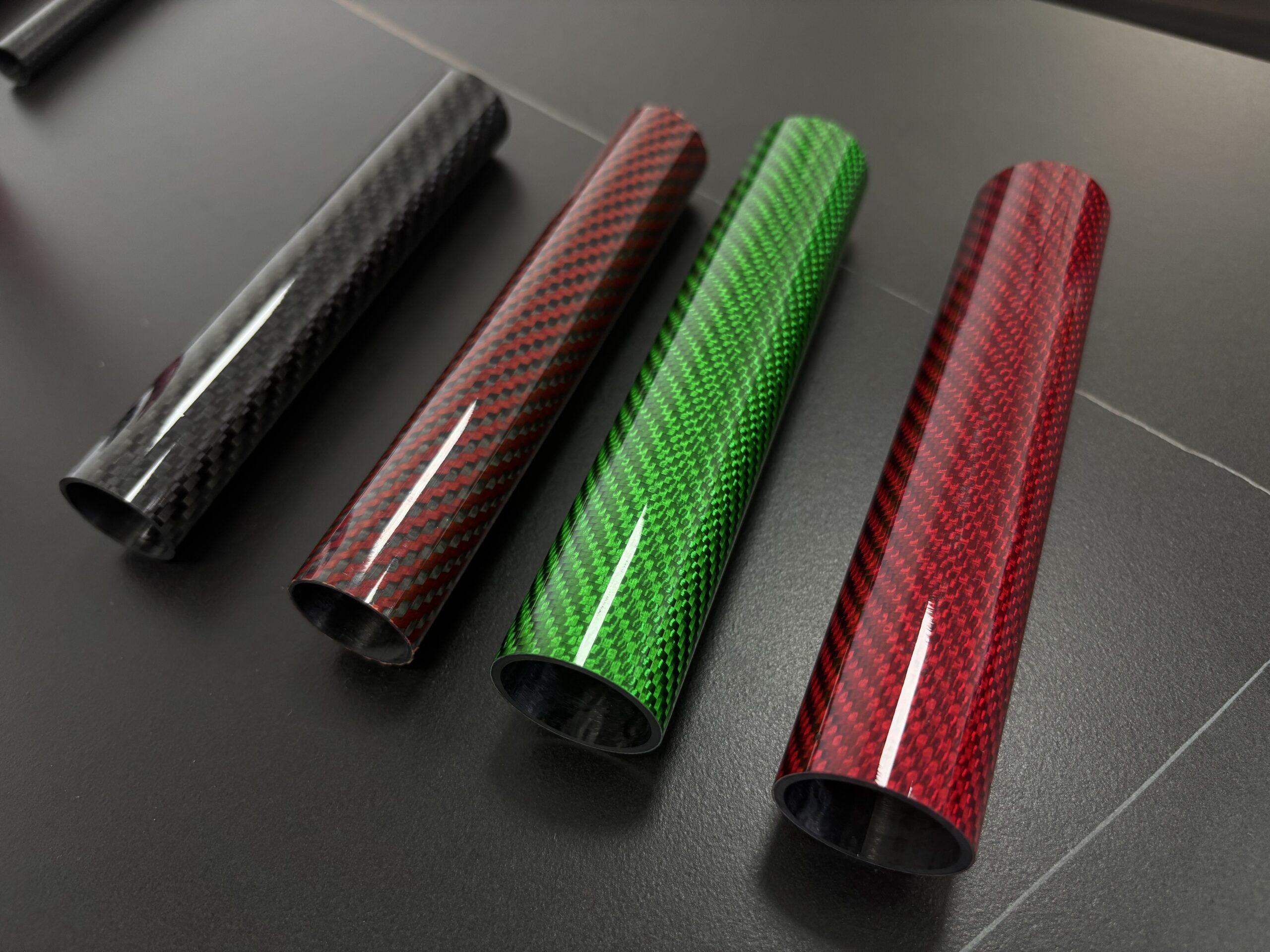

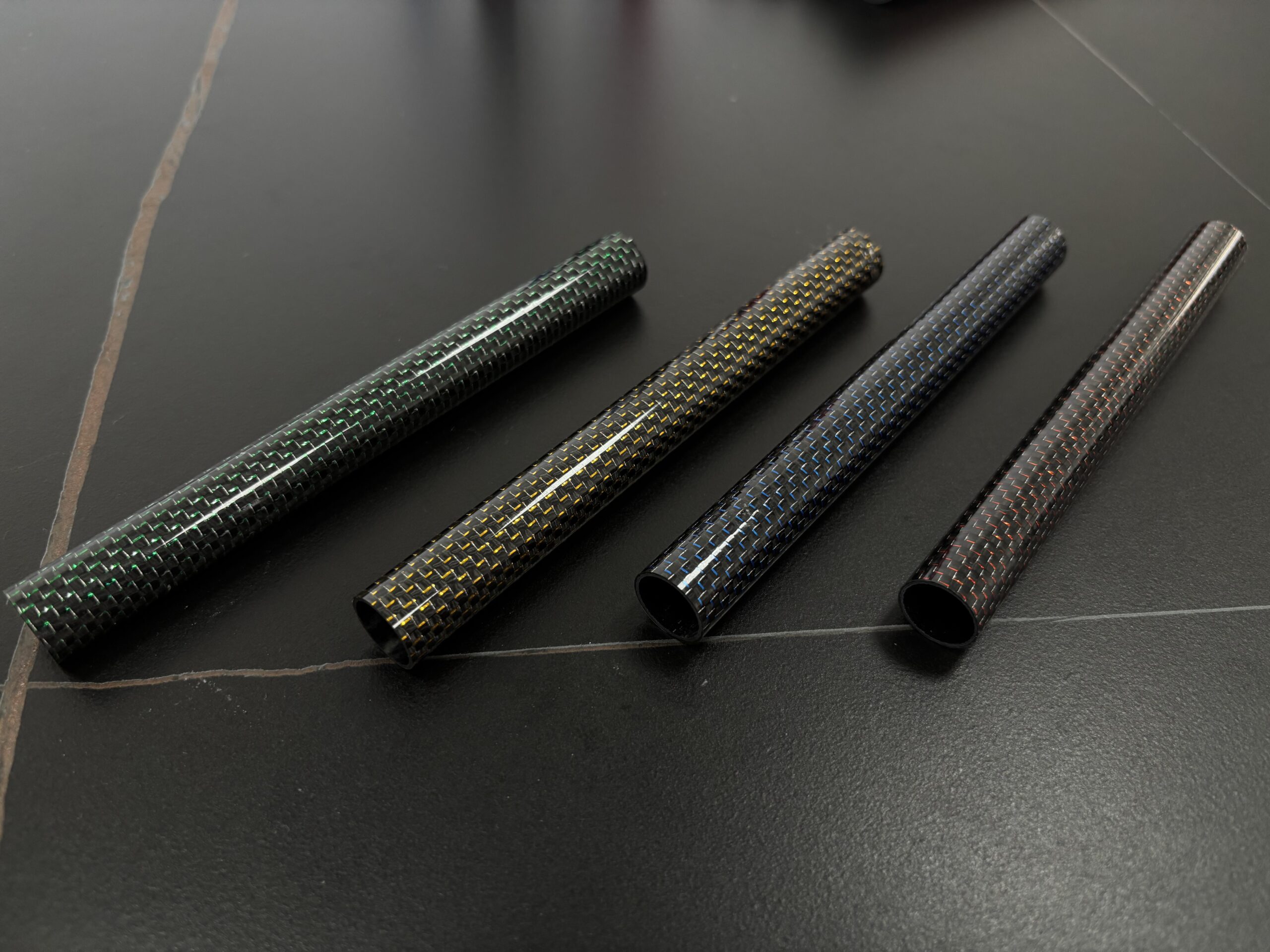

Maßgeschneiderte Optionen für das Erscheinungsbild

Unsere Kohlefaserrohre können exakt an Ihre ästhetischen Anforderungen angepasst werden:

-

Muster weben: Unidirektional, 3K, 1K, Leinwandbindung, Köperbindung, Geschmiedete Mable

-

Farben: Erhältlich in einer breiten Palette von Farben

-

Oberfläche: Glänzende oder matte (Satin) Optionen

Wir helfen Ihnen dabei, ein Produkt zu entwickeln, das ebenso fortschrittlich aussieht wie es funktioniert. info@carbonfibercfk.com

Prüfen Sie, wie stark unsere Rohre sind

Unsere fortschrittlichen Kohlefaserrohre wurden für hervorragende Leistungen entwickelt und definieren die Leistungsstandards neu. Diese besondere 32mm OD / 24mm ID Rohr wird mit einer präzisen Wandstärke von 4 mm unter Verwendung automatisierter Prozesse und hochwertiger Verbundwerkstoffe für die Luft- und Raumfahrt hergestellt, um eine gleichbleibende, zuverlässige Qualität zu gewährleisten.

Abgesehen von seinen beeindruckend leichten Eigenschaften ist dieses Rohr so konstruiert, dass es erheblichen mechanischen Belastungen standhält. Es wurde validiert, um erhebliche Radiallasten bis zu 605 kg, Das macht es zu einer idealen Lösung für hochbelastete strukturelle Anwendungen wie Roboterarme, Hochleistungsmaschinen, Automobilsysteme und Sportgeräte.