At E-YOUNG Composites, we specialize in manufacturing top-tier carbon fiber and glass fiber products designed to meet the most demanding industrial applications. One of the key technologies that set us apart is pullwinding—an advanced variant of the traditional pultrusion process. In this article, we explore how pullwinding enables the production of high-performance composite tubes with exceptional precision, strength, and reproducibility.

What Is Pullwinding?

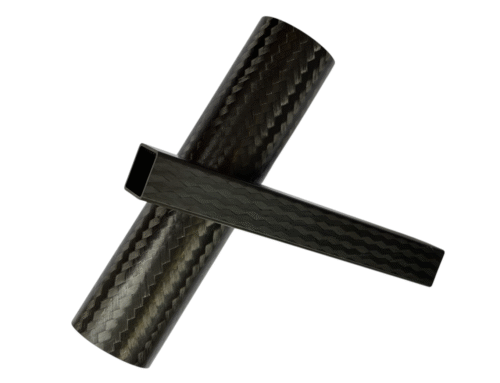

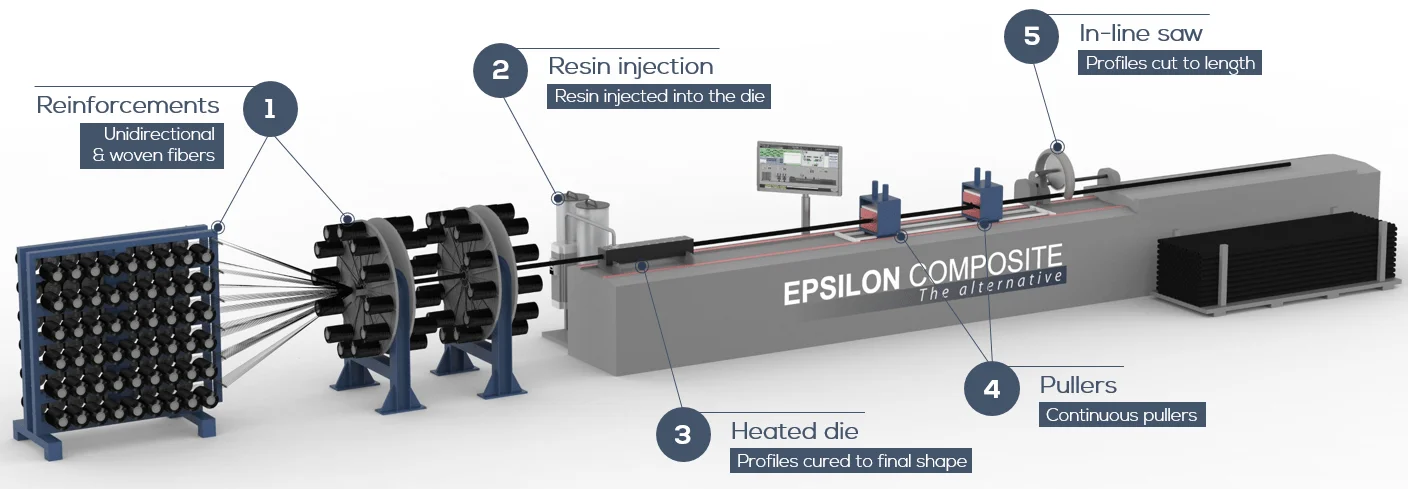

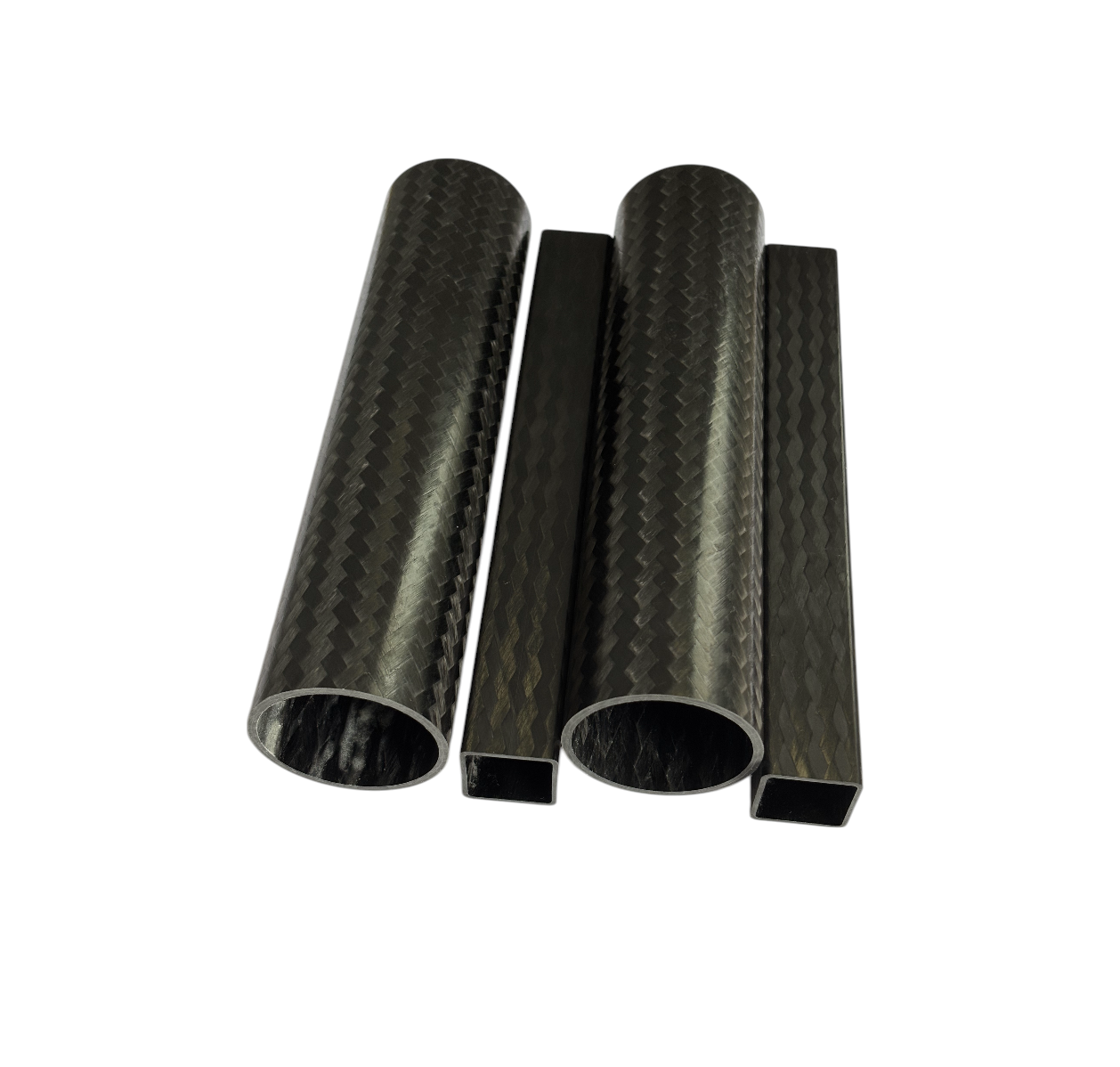

Pullwinding combines the continuous production benefits of pultrusion with the enhanced fiber placement capabilities of filament winding. The term “pullwinding” is derived from “pull” (from pultrusion) and “winding.” This hybrid process involves pulling carbon or glass fibers through a resin impregnation system, then precisely winding them at specified angles (from 0° to 90°) before curing in a heated die. The result is a composite tube with optimized mechanical properties and a superior surface finish.

Why Choose Pullwinding for Your Composite Components?

Pullwinding offers several distinct advantages over conventional composite manufacturing methods:

-

High Fiber Volume Ratio (60-75%)

Achieve a fiber volume content of 60-75%—significantly higher than the 50-55% typical of other processes. This results in stronger, lighter, and more durable components. -

Low Permeability (<2%)

Enjoy enhanced resistance to moisture and chemicals, making our pullwound tubes ideal for harsh environments. -

Optimal Fiber Alignment

Customize fiber orientation from 0° to 90° to meet specific load and performance requirements. -

Net Shape Finish

Our pullwound tubes exhibit an excellent surface appearance straight out of the die, eliminating the need for additional machining or finishing. -

Excellent Reproducibility

With automated, 24/7 production capabilities, we ensure consistent quality and high yields across all orders.

Materials and Flexibility

At E-YOUNG Composites, we use spools of carbon, glass, aramid, or natural fibers, along with high-performance resin systems (including epoxide thermosets and thermoplastics). This raw material approach provides greater flexibility and cost efficiency compared to using pre-impregnated fabrics or textiles.

Thermosets vs. Thermoplastics in Pullwinding

While thermosetting resins (such as epoxies) often deliver the best balance of performance, durability, and cost for pultrusion applications, E-YOUNG also offers thermoplastic composite solutions. Thermoplastic pullwinding provides benefits like improved recyclability, impact resistance, fire retardancy, and weldability. Our expertise in both material types ensures we can recommend the ideal solution for your project.

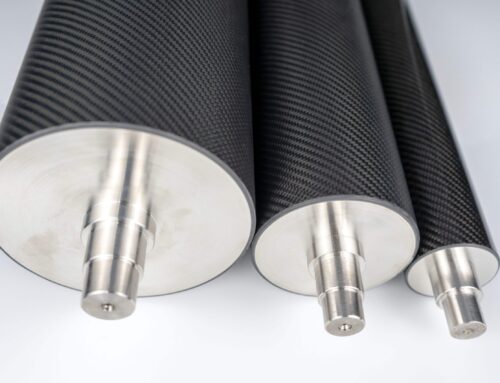

Partner with E-YOUNG Composites for Your Pullwinding Needs

With years of experience in composite manufacturing, E-YOUNG Composites is your trusted partner for high-quality pullwound carbon fiber and glass fiber tubes. Our state-of-the-art production facilities and commitment to innovation allow us to meet the evolving needs of industries such as aerospace, automotive, sports equipment, and more.

Ready to elevate your products with pullwinding technology?

Contact us at info@carbonfibercfk.com or visit our website to request a quote and learn how E-YOUNG Composites can support your next project.

Learn more about Pullwinding Products https://carbonfibercfk.com/products/braided-reinforced-pultruded-tubes/