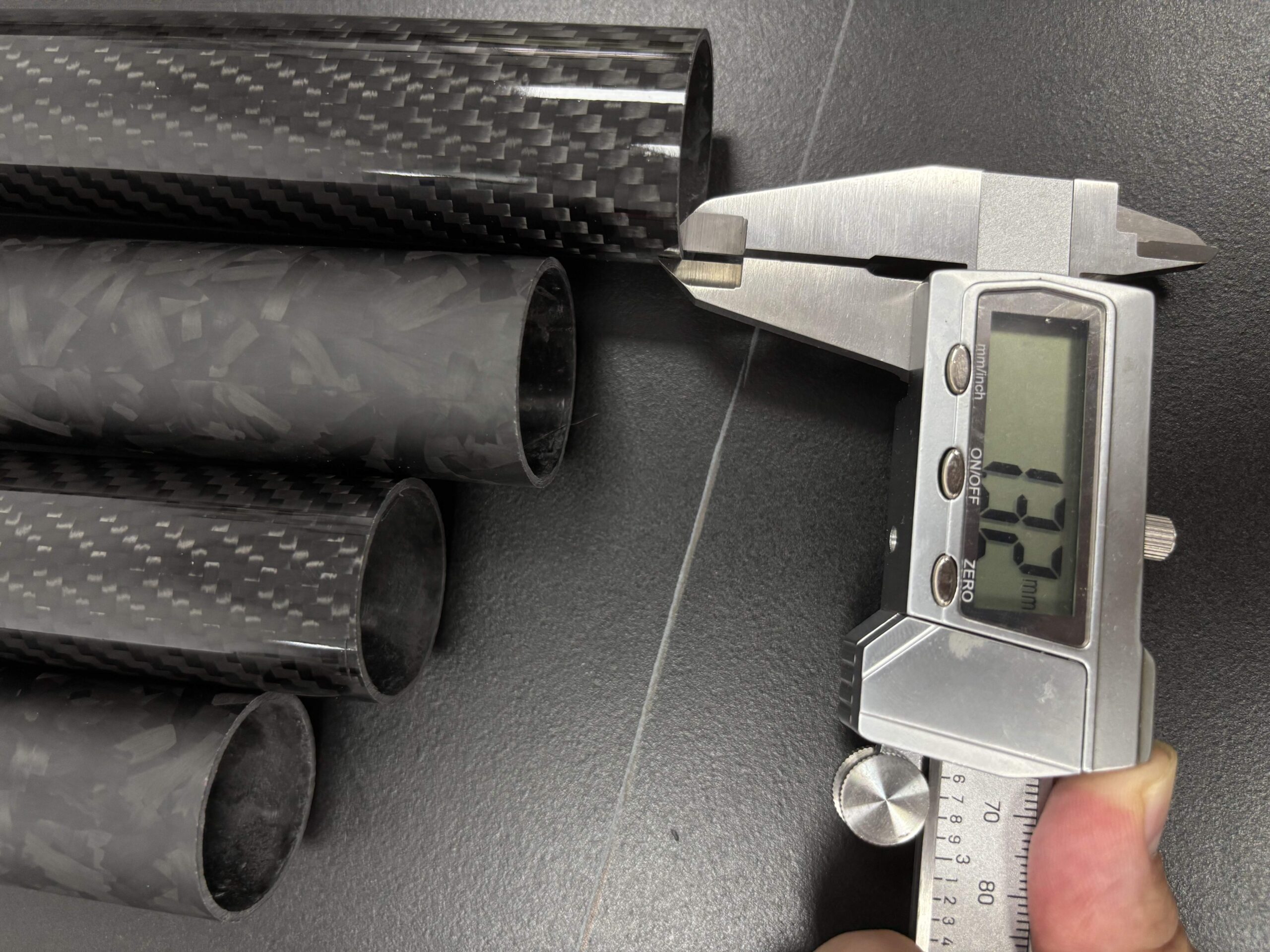

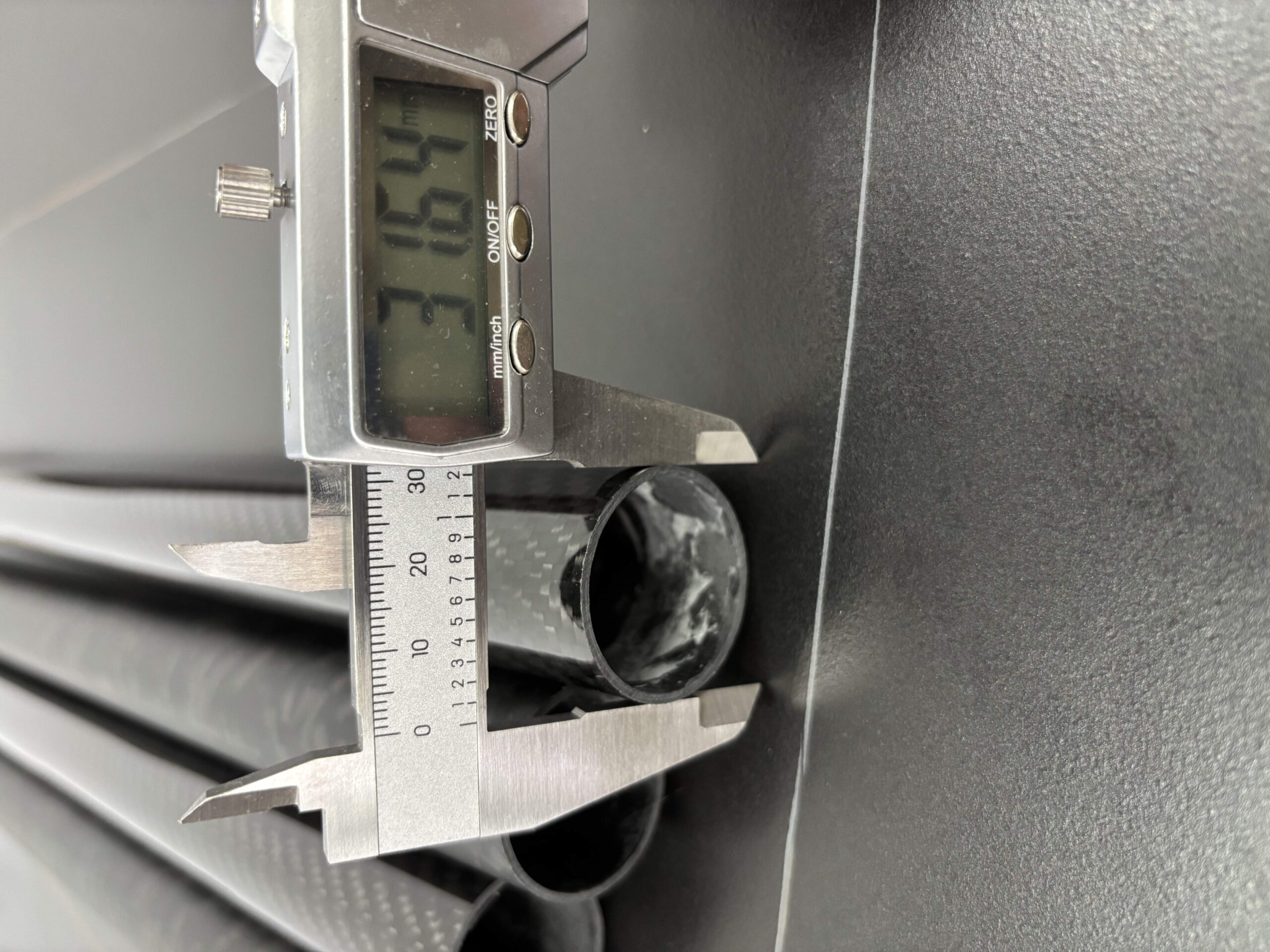

Carbon Fiber Rolled Tubes with Forged Surface

E-YOUNG Composites specializes in advanced carbon fiber rolled tubes that combine maximum axial strength with a stunning forged carbon aesthetic. Our unique process utilizes an internal layer of unidirectional (UD) carbon fiber prepreg for structural performance, finished with an outer layer of forged carbon prepreg for a distinctive marble pattern. This is the ideal solution where both performance and visual impact are critical.

Core Technology & Benefits

The Core: Axial Strength

Aerospace-grade Unidirectional (UD) Carbon Fiber Prepreg

Provides exceptional strength and stiffness along the tube’s length. Ideal for applications dealing with high bending loads, such as push rods, drone arms, and structural supports.

The Surface: Beauty & Durability

Forged Marble Carbon Fiber Prepreg

Creates a unique, high-end cosmetic finish that is lightweight and scratch-resistant. Each tube has a one-of-a-kind pattern.

The Process: Precision Rolling

Computer-controlled mandrel wrapping and curing.

Ensures excellent consistency, precise wall thickness control, and high-quality inner surface finish.

Types of Carbon Fiber Available

| Caractéristiques | T300 | T700 | T800 |

|---|---|---|---|

| Densité (g/cm³) | 1.55 | 1.55 | 1.55 |

| Résistance à la traction (MPa) | 3400 | 4900 | 5200 |

| Module d'élasticité (GPa) | 240 | 250 | 295 |

| Élongation (%) | 1.78 | 1.76 | 1.7 |

Applications

-

High-Performance Automotive: Custom push rods, stabilizer bars, linkage arms 。

-

Aerospace & UAV: Drone arms and landing gear 。

-

Automatisation industrielle : Robotic arms and frames 。

-

Consumer Goods & Sports: Luxury watch rolls, high-end bicycle seat posts, fishing rods, architectural elements。

FAQ

-

Q: What are the main benefits of a UD inner layer compared to all forged carbon?

-

A: A UD inner layer provides significantly higher strength and stiffness in the axial direction, making the tube much more efficient at resisting bending forces. An all-forged carbon tube is more isotropic (similar properties in all directions) but less strong in a specific direction.

-

-

Q: Can the thickness of the UD and forged layers be customized?

-

A: Absolutely. This is a key advantage of our process. We can adjust the number of UD layers to meet your structural requirements and apply the forged layer as the final cosmetic ply.

-

-

Q: What is the lead time for prototyping?

-

A: Typical prototyping lead time is 2-3 weeks after design confirmation.

-

Feel free to reach out for a quote info@carbonfibercfk.com