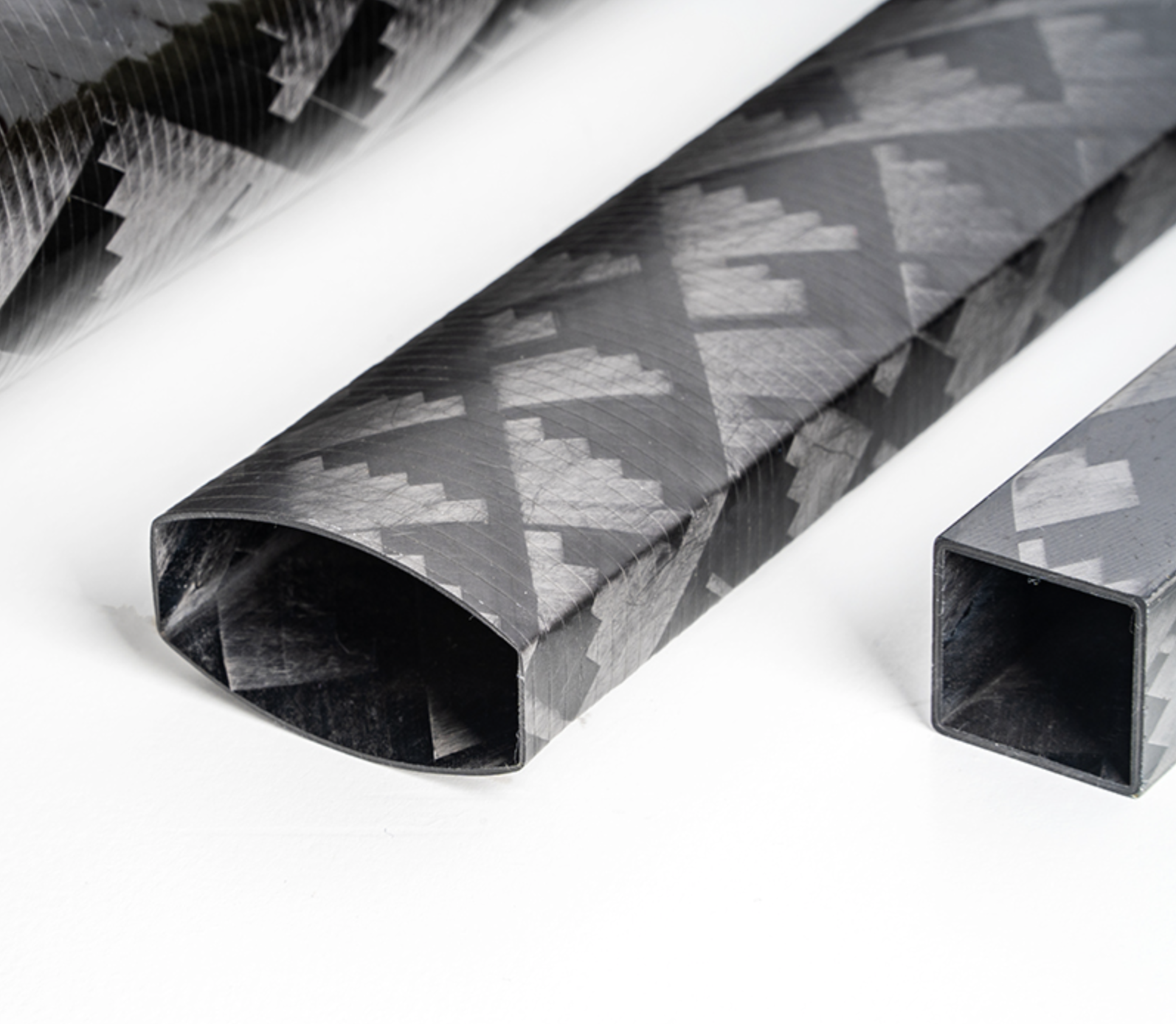

Tubes en fibre de carbone à enroulement filamentaire

Our filament wound carbon fiber tubes represent the pinnacle of composite engineering, combining aerospace-grade materials with advanced manufacturing techniques. Utilizing continuous carbon fiber filaments impregnated with high-performance resins, these tubes are wound under precise computer-controlled conditions to deliver exceptional strength-to-weight ratios and dimensional consistency.

Nos avantages

High-quality Raw materials

Dimensions

Shapes

Angle d'enroulement du filament

When not specified we use cross-winding at 15 degrees (for bending load), or 45 degrees (for torsion load). if you are not familer about the filament winding angle, click here to learn more https://carbonfibercfk.com/understanding-filament-winding-angles-in-carbon-fiber-tubes/

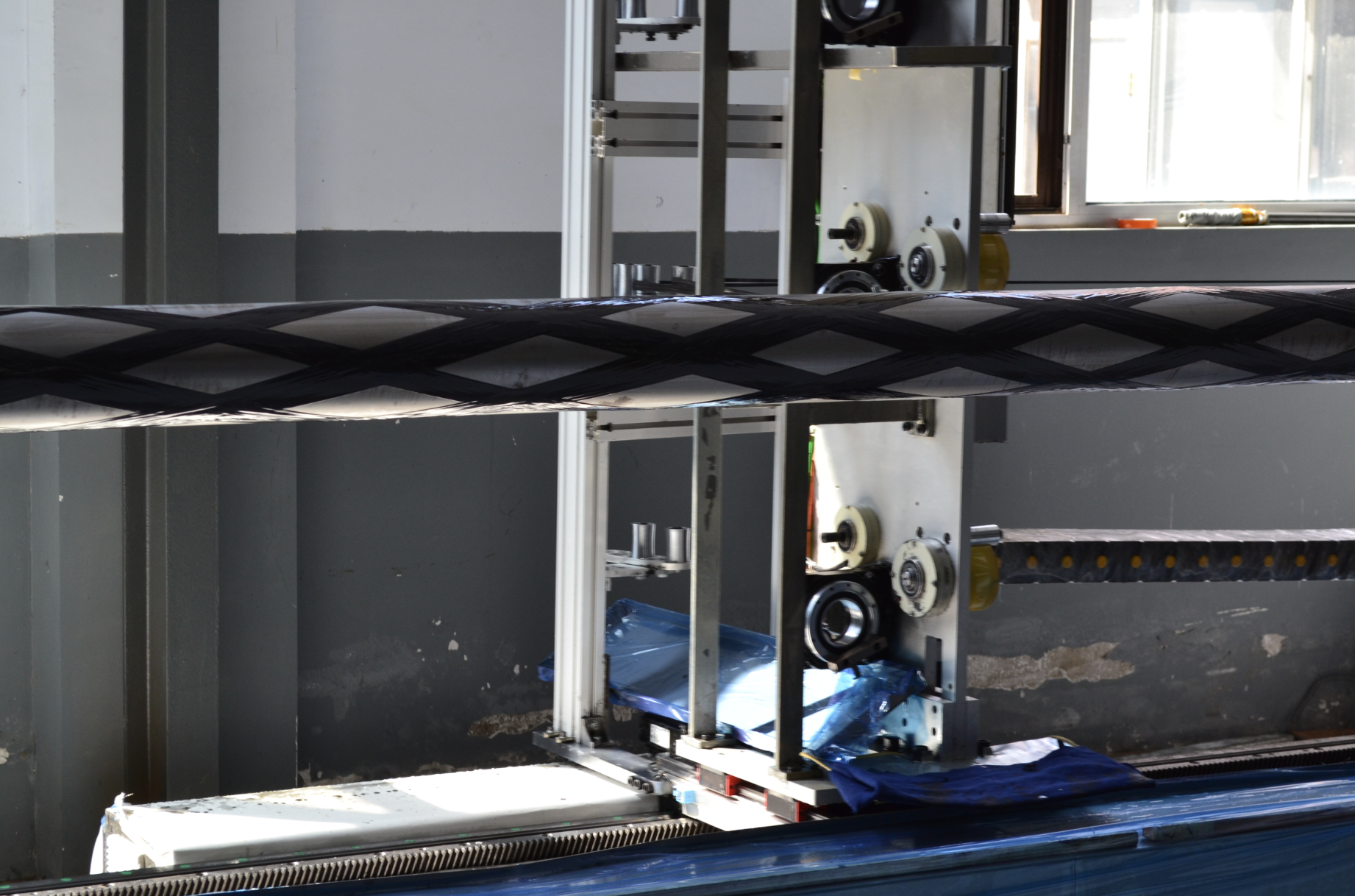

Tubes in Processing