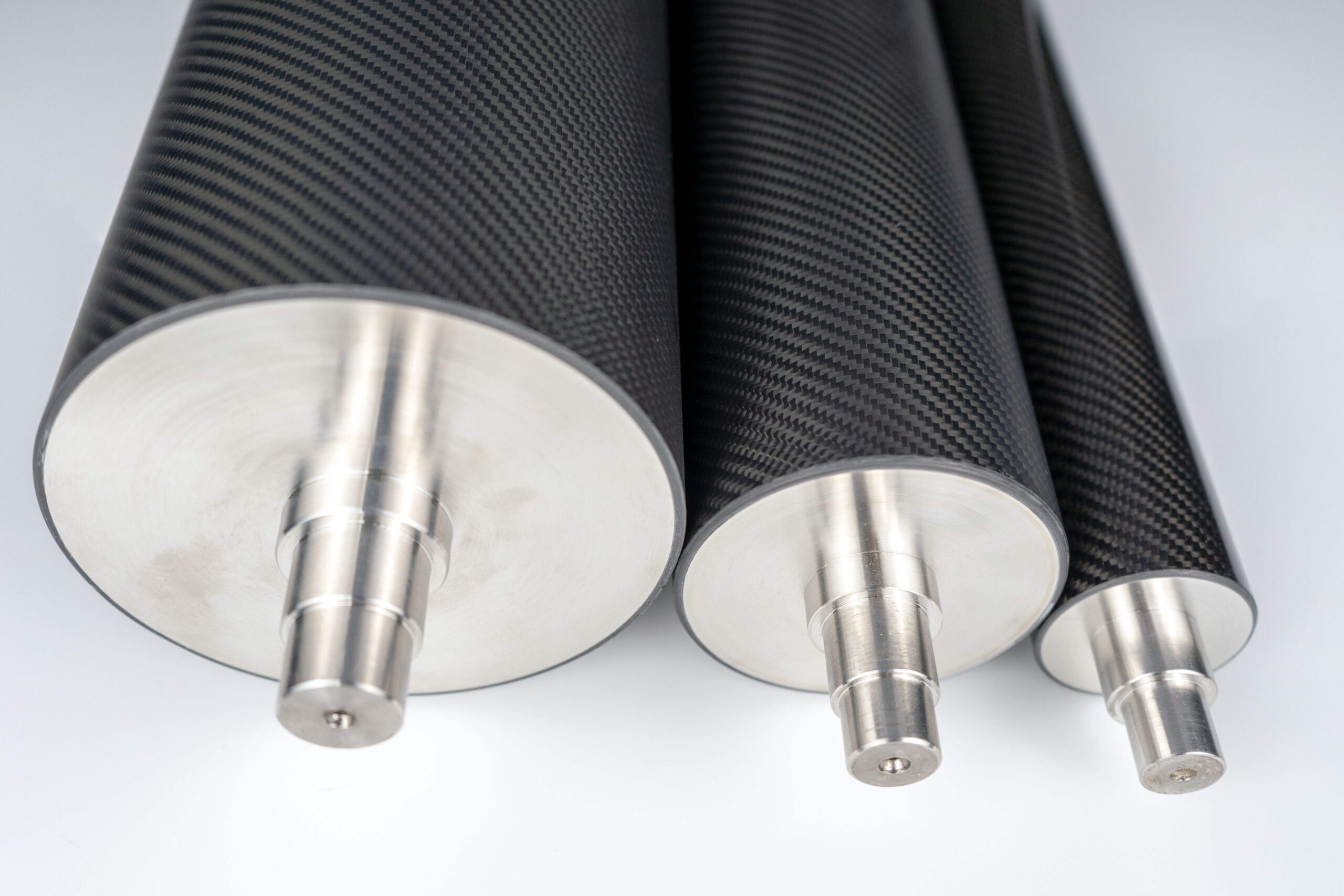

Carbon fiber round tubes serve as critical components in applications where precision is non-negotiable. From aerospace frameworks to robotic actuators and high-performance automotive systems, roundness tolerance directly impacts functionality and performance. Even minor ovality can cause assembly issues, reduce structural integrity, and compromise operational efficiency.

At E-YOUNG Composites, we’ve mastered the art of manufacturing carbon fiber round tubes with exceptional circularity through advanced roll-wrapping technology. Here’s how we ensure every tube meets stringent roundness specifications.

Why Roundness Matters in Carbon Fiber Tubes

Carbon fiber round tubes must maintain consistent diameter to ensure:

- Seamless Assembly: Perfect fit with bearings, connectors and other cylindrical components

- Structural Performance: Uniform stress distribution under load

- Operational Efficiency: Consistent performance in rotational applications

Even 0.1mm deviation can cause significant problems in precision applications.

5 Key Techniques for Perfect Roundness in Roll-Wrapped Tubes

1. Precision Mandrel Systems

Our manufacturing process begins with custom-engineered mandrels manufactured to tolerances within ±0.01mm. Each mandrel undergoes:

- Regular dimensional verification

- Surface quality inspection

- Thermal expansion testing

2.Computer-Controlled Tension Management

We utilize advanced tension control systems that maintain consistent fiber tension throughout the winding process, preventing variations that can cause ovality.

3.Balanced Ply Architecture

Our engineers design symmetric ply sequences that balance stresses throughout the structure, preventing deformation during curing and cooling.

4.Controlled Curing Environment

We employ precisely calibrated autoclaves that maintain:

- Uniform temperature distribution (±1.5°C)

- Consistent pressure application

- Controlled ramp rates

5.Comprehensive Dimensional Verification

Every production batch undergoes rigorous inspection using:

- Laser micrometer systems

- Coordinate measuring machines (CMM)

- Optical comparators

We typically achieve roundness tolerances within ±0.5mm,

with even tighter tolerances available for specialized applications.

Why Choose E-YOUNG Composites?

When you partner with us for your carbon fiber round tubes, you benefit from:

- Proven Expertise: Decades of specialized composite manufacturing experience

- Advanced Technology: State-of-the-art roll-wrapping equipment

- Quality Assurance: Comprehensive inspection documentation

- Custom Solutions: Tailored to your specific requirements

Ready to Discuss Your Project?

Contact E-YOUNG Composites today for carbon fiber tubes that meet your most demanding roundness specifications. Request a quote or technical consultation to get started. info@carbonfibercfk.com