When designing and working with materials, especially composite materials like carbon fiber reinforced plastics (CFRP), it is essential to understand the differences between isotropic, quasi-isotropic, and anisotropic materials. These properties define how a material reacts to forces applied in different directions, influencing strength, stiffness, and overall performance.

Isotropic Materials

Definition:

An isotropic material has the same mechanical properties in all directions. This means that its strength, stiffness, and elasticity remain constant regardless of the direction of the applied force.

Examples:

- Metals (e.g., steel, aluminum, titanium)

- Glass

- Plastics

Characteristics:

✅ Uniform strength and stiffness in all directions

✅ Easy to analyze and predict mechanical behavior

✅ Common in general engineering applications

Applications in Carbon Fiber Composites:

- Carbon fiber itself is not isotropic, but isotropic properties can be achieved using randomly oriented short fibers in composite materials.

- Used in automotive and aerospace industries for impact-resistant parts and uniform load distribution.

Quasi-Isotropic Materials

Definition:

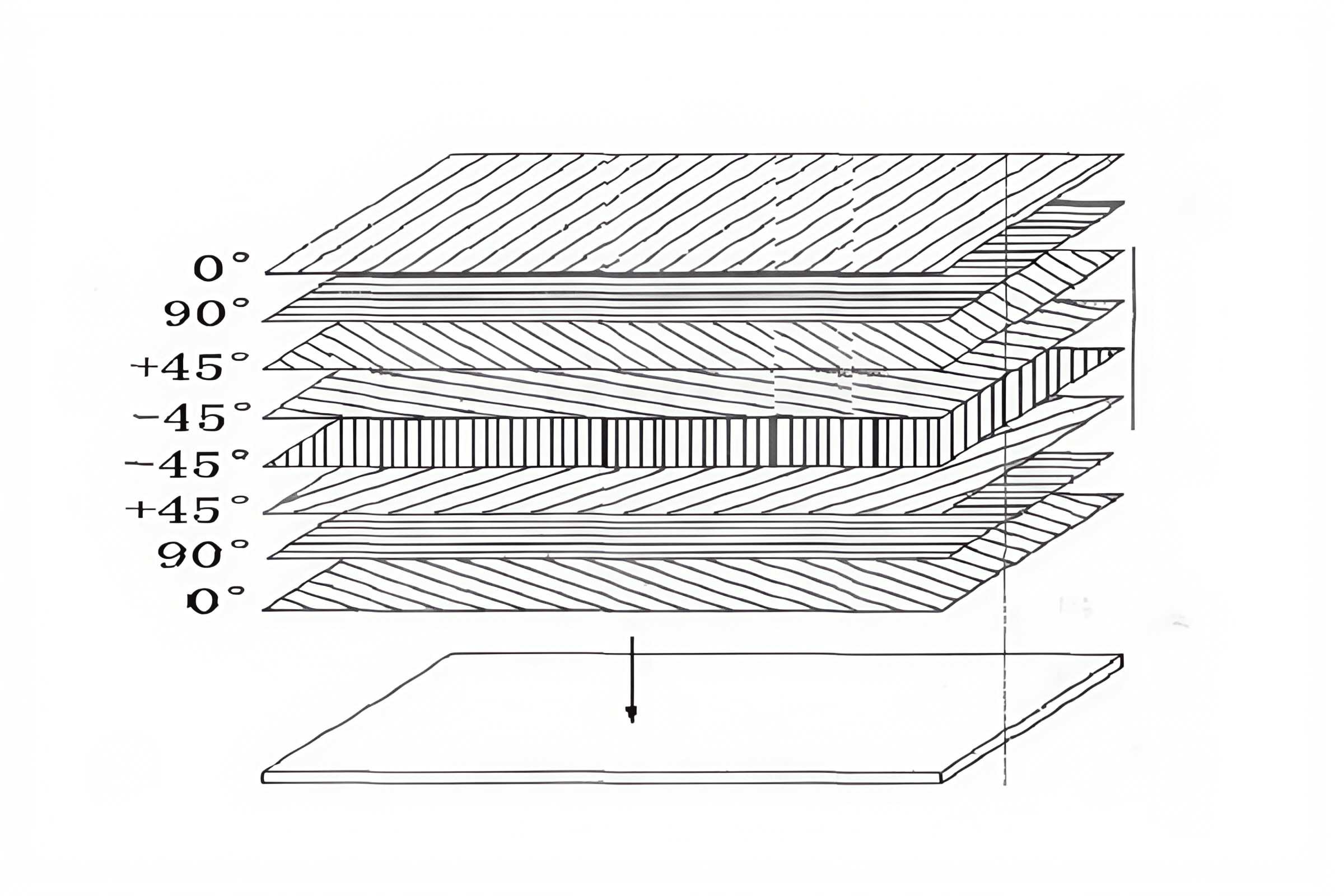

A quasi-isotropic material has isotropic properties within a specific plane (typically the in-plane direction of a composite laminate). This means that strength and stiffness are equal in all in-plane directions, but they may vary through the thickness of the material.

How It Is Achieved in CFRP:

- By orienting fibers in multiple balanced directions, such as 0°, 90°, +45°, and -45°.

- Another method involves 0°, 60°, and 120° fiber orientations.

Characteristics:

✅ Strength and stiffness are uniform within the plane

✅ More balanced load distribution compared to anisotropic laminates

✅ Common in multi-directional load-bearing applications

Applications in Carbon Fiber Composites:

- Aerospace structures (e.g., aircraft fuselage, wing skins)

- Automotive body panels (ensuring uniform strength and stiffness)

- High-performance sports equipment (e.g., bicycle frames, tennis rackets)

Anisotropic Materials

Definition:

An anisotropic material has different mechanical properties in different directions. This means that its strength, stiffness, and response to loads depend on fiber orientation.

Examples:

- Wood: Stronger along the grain than across it.

- Carbon fiber laminates: Maximum strength along fiber direction but weaker perpendicular to fibers.

Characteristics:

✅ Extremely strong in the fiber direction

✅ High strength-to-weight ratio

✅ Requires precise design to avoid weak points

Applications in Carbon Fiber Composites:

- Unidirectional (UD) carbon fiber laminates are highly anisotropic, offering maximum strength in one direction.

- Used in high-performance applications where loads are mainly in a single direction, such as:

- Aerospace beams and spars

- Racing car chassis

- Bicycle frames

Comparison of Properties

| Property | Isotropic | Quasi-Isotropic | Anisotropic |

|---|---|---|---|

| Strength & Stiffness | Same in all directions | Equal in-plane, varies through thickness | Highest in fiber direction, weakest in others |

| Typical Material | Metals, glass, plastics | Balanced fiber-reinforced composites | Unidirectional carbon fiber |

| Carbon Fiber Layup | Random short fibers | 0°, ±45°, 90° or 0°, 60°, 120° | Unidirectional (UD) layups |

| Applications | General engineering | Aerospace, automotive, sports | Racing, aerospace spars, bike frames |

Conclusion

Understanding isotropic, quasi-isotropic, and anisotropic properties is essential for optimizing carbon fiber composite designs. The choice between these materials depends on specific load requirements, desired strength and stiffness, and application needs.

Feel free to reach out https://carbonfibercfk.com/contact-us/ or contact us by email info@carbonfibercfk.com