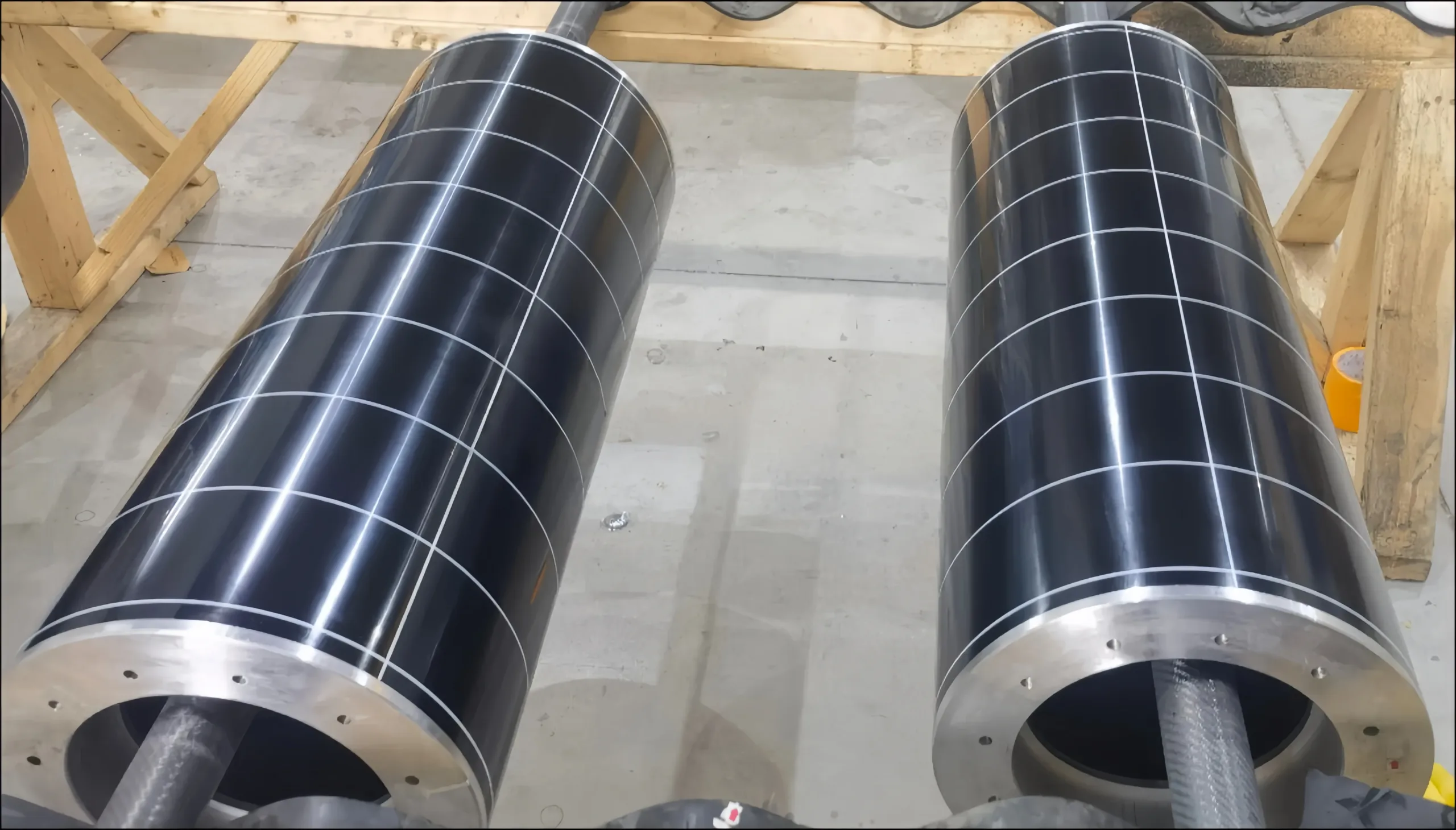

Carbon Fiber Roller for Textile, Lithium Battery & Printing Industries

E-YOUNG Composites is a specialist manufacturer of carbon fiber rollers for high-speed, high-precision industrial applications. Our rollers are widely used in textile machinery, lithium battery production lines, printing systems, slitting equipment, coating lines, and unwinding/rewinding systems.

With over 15 years of composite manufacturing experience, we provide OEM/ODM solutions tailored to demanding industrial environments. Our facility uses aerospace-grade carbon fiber prepreg, CNC mandrel winding, autoclave curing, and dynamic balancing to ensure maximum stiffness and lowest inertia.

Typical Applications

Textile Industry

-

high-speed spinning

-

draw frame rollers

-

tension rollers

-

winding & guiding rollers

Lithium Battery Industry

-

electrode coating rollers

-

calendering guide rollers

-

film handling rollers

-

drying line rollers

Printing & Packaging

-

anilox system

-

coating & laminating rollers

-

slitting and rewinding machines

-

high-precision transport rollers

Why Choose E-YOUNG Carbon Fiber Rollers?

1. Ultra-Lightweight (Up to 70% Lighter than Steel)

Reducing roller weight significantly improves:

- acceleration & deceleration response

- machine efficiency

- energy savings

- reduced bearing load

This is especially critical for lithium battery coating/lamination e high-speed textile machinery.

2. High Stiffness & Low Deflection

Using T700/T800 carbon fiber prepreg, our rollers achieve:

- excellent bending stiffness

- minimal thermal deformation

- stable performance at high RPM

Ideal for precision printing e ultra-thin film production.

3. Excellent Dynamic Balance

Each roller undergoes:

- CNC dynamic balancing

- 0.01–0.03mm TIR control

- high-speed rotation testing

Ensures vibration-free operation, extending machine life.

4. Corrosion-Resistant & Long Service Life

CFRP rollers are resistant to:

- chemicals

- solvents

- moisture

- high temperatures

Perfect for coating lines, printing, e battery electrode processes.

Specifiche tecniche

| Parameter | Specifiche |

|---|---|

| Materiale | T300 / T700 / T800 Carbon Fiber Prepreg |

| Diameter | 20mm – 500mm |

| Lunghezza | Up to 6000mm |

| Surface | Matte / Glossy / Rubber-coated / Customized |

| Concentricity | ≤ 0.03mm |

| Straightness | ≤ 0.02mm / m |

| Trattamento della superficie | Ceramic coating, PU rubber, anodized aluminum end caps |

| Process | Roll Wrap or Filament winding / Autoclave curing / High-speed balancing |

Customization Options

- Roller diameter & length

- Carbon fiber grade: T300 / T700 / T800

- Fiber orientation (0°, ±45°, 90°)

- Rubber coating thickness

- Aluminum, steel, or titanium end caps

- Dynamic balancing level

- Surface roughness

- Anti-static or insulating design

Learn More about how to customize carbon fiber roller

Why E-YOUNG Composites?

- 15+ years composite manufacturing experience

- OEM supplier for global textile & battery equipment companies

- In-house engineering & FEA simulation

- Autoclave + filament winding + CNC machining

- Strict QC: wall thickness, stiffness, deflection, concentricity, balancing

- Strong export capability to EU / USA markets

E-mail: info@carbonfibercfk.com