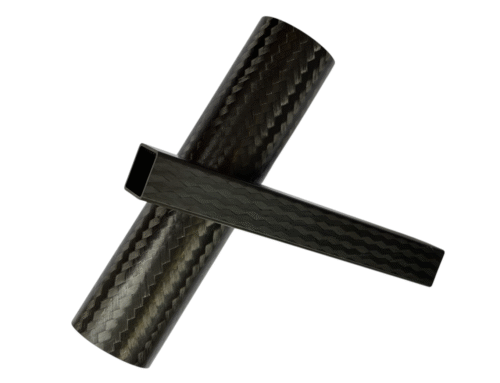

High-Strength Pull Wound Carbon Fiber Tube for Heavy-Lift Drones

Engineered for the demanding requirements of the modern aerospace and UAV industry, E-YOUNG Composites’ Pull Wound Tube represents the pinnacle of lightweight structural design. Utilizing the advanced pull winding manufacturing process, this tube delivers an unparalleled strength-to-weight ratio and exceptional torsional stiffness, making it the ideal choice for large, heavy-lift drone arms where performance and reliability are non-negotiable.

Key Features & Benefits

-

Superior Stiffness & Strength: The unique pull winding process aligns continuous carbon fibers in a helical pattern, optimizing the tube for multidirectional loads experienced by drone arms in flight.

-

Ultra-Lightweight: Significantly lighter than aluminum or steel, reducing the overall weight of your UAV and extending flight time and payload capacity.

-

Exceptional Durability: High resistance to fatigue, corrosion, and impact, ensuring long-term performance in harsh operational environments.

-

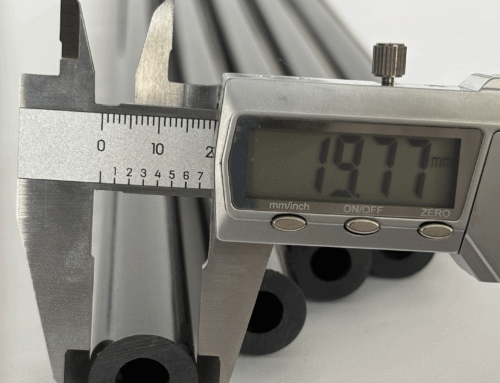

Precision Engineering: Consistent wall thickness and excellent concentricity for reliable and predictable performance in every batch.

-

Customizable Inner Diameter: Tailor the tube’s properties to your specific needs with available inner diameters of 44mm, 45mm, or 46mm.

기술 사양

-

Product: Pull Wound Carbon Fiber Tube

-

Primary Application: Heavy-Lift Drone Arm / UAV Structural Component

-

제조 프로세스: Pull Winding

-

Outer Diameter (OD): 50 mm (Standard)

-

Inner Diameter (ID): 44 mm, 45 mm, 46 mm (Customizable upon request)

-

Material: High-Modulus Carbon Fiber & Epoxy Resin

-

Minimum Order Quantity (MOQ): 300 meters

-

길이: Custom lengths available

Why Choose E-YOUNG’s Pull Winding Technology?

The pull winding process combines the benefits of pultrusion (high continuous fiber volume) and filament winding (optimized hoop strength). This results in a composite tube with:

-

Higher axial strength than filament-wound tubes.

-

Better crush resistance and hoop strength than pultruded tubes.

This makes it perfectly suited for drone arms that must resist bending moments and torsional forces simultaneously.

애플리케이션

-

Heavy-Lift Unmanned Aerial Vehicle (UAV) Arms

-

Agricultural Spraying Drones

-

Delivery & Logistics Drones

-

Industrial Inspection UAVs

-

Other robotic and automated structural components requiring high stiffness and low weight.

Ready to Enhance Your Drone’s Performance?

Leverage the advanced properties of our pull-wound carbon fiber tubes for your next project. Our technical team at E-YOUNG Composites is ready to support you from prototype to production.

Email us directly at: info@carbonfibercfk.com