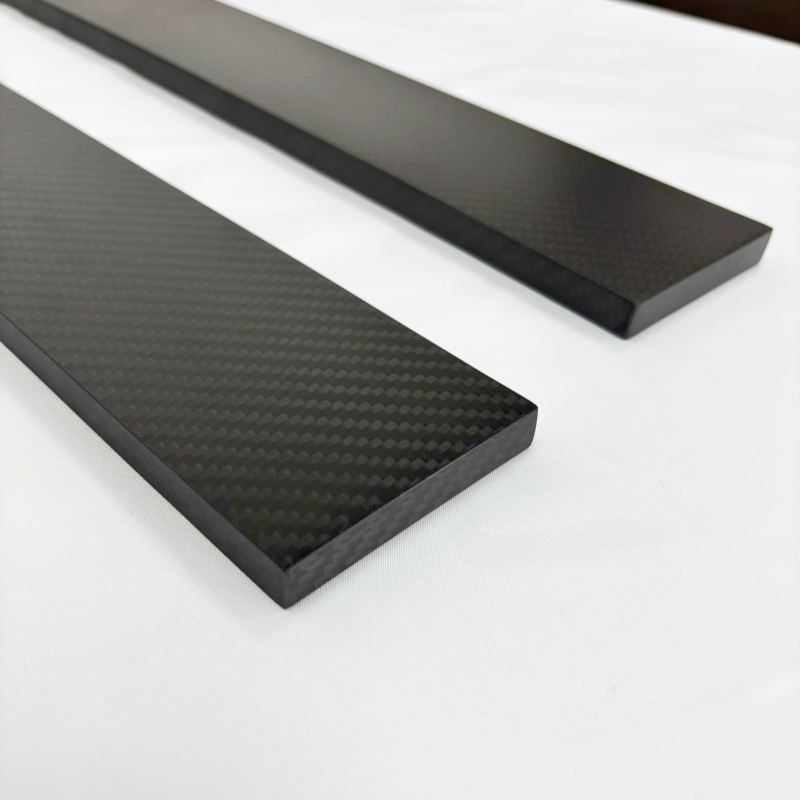

Carbon Fiber Sandwich Panels with Full Carbon Edging.

Porquê escolher painéis sanduíche de fibra de carbono?

Carbon fiber sandwich panels combine aerospace-grade performance with architectural elegance. By bonding a lightweight core between two carbon fiber layers, they deliver:

- Ultra-High Strength-to-Weight Ratio: 50% lighter than steel, yet 5x stronger.

- Corrosion & Fatigue Resistance: Ideal for harsh environments (marine, industrial).

- Sleek Aesthetic Appeal: 3K twill weave adds a luxury finish for visible applications.

- Customizable Rigidity: Adjust core materials and thickness for your load requirements.

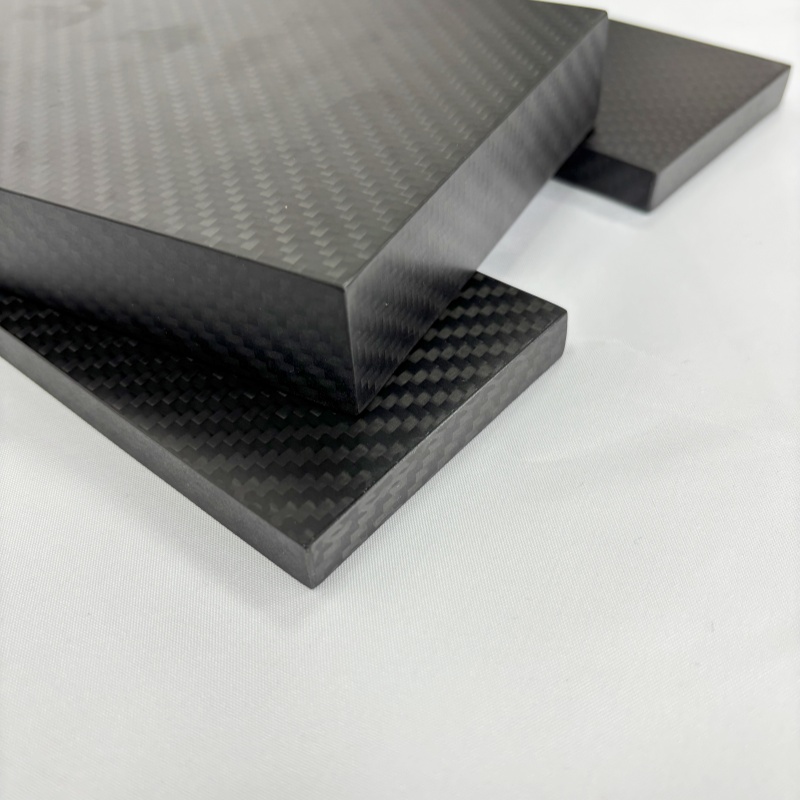

Premium Edge Finishing: Full Carbon Encapsulation

Unlike traditional sandwich panels with exposed core edges, our Full Carbon Edging technology wraps all six faces in continuous carbon fiber sheets. This process:

- Eliminates Core Exposure: No visible foam or honeycomb at edges.

- Enhances Durability: Sealed edges prevent moisture ingress and delamination.

- Streamlines Aesthetics: Seamless carbon finish for high-end architectural projects.

Aplicações: Luxury interiors, automotive trim, yacht components, and exposed structural elements.

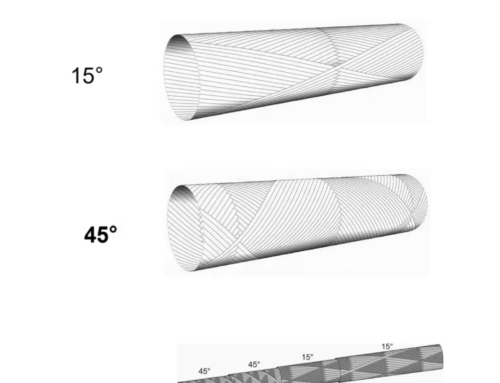

Tailored to Your Needs: Core & Carbon Options

Core Materials (Custom Thickness Available):

PVC/PMI Foam Core: Best for vibration damping & thermal insulation.

Aluminum Honeycomb Core: Maximum strength for aerospace/defense.

Aramid Paper/PP Honeycomb Core: Fire-resistant & eco-friendly.

Wood Core: Natural aesthetics for architectural cladding.

Carbon Fiber Grades:

- T300: Cost-effective for general-purpose use.

- T700: High stiffness-to-weight ratio for automotive/robotics.

- T800: Premium aerospace-grade tensile strength.

contacte-nos em https://carbonfibercfk.com/contact-us/ ou no correio eletrónico info@carbonfibercfk.com

Deixar um comentário