A escolha da fibra de carbono errada pode aumentar os custos em 40% e provocar o fracasso do projeto. Este guia de seleção de fibra de carbono revela como os engenheiros aeroespaciais, automóveis e robóticos selecionam os materiais ideais.

1. Compreender os fundamentos da fibra de carbono

Propriedades principais:

- Elevada relação resistência/peso (5x mais forte do que o aço com 1/4 do peso)

- Elevada relação rigidez/peso

- Baixa expansão térmica

- Excelente resistência à fadiga

- Resistência à corrosão

- Condutividade eléctrica

- Anisotrópico: As propriedades variam com a direção da fibra.

2. Parâmetros críticos de seleção

- Unidirecional (UD): Fibras todas em 0°. Resistência/rigidez máxima na direção primária. Laminados.

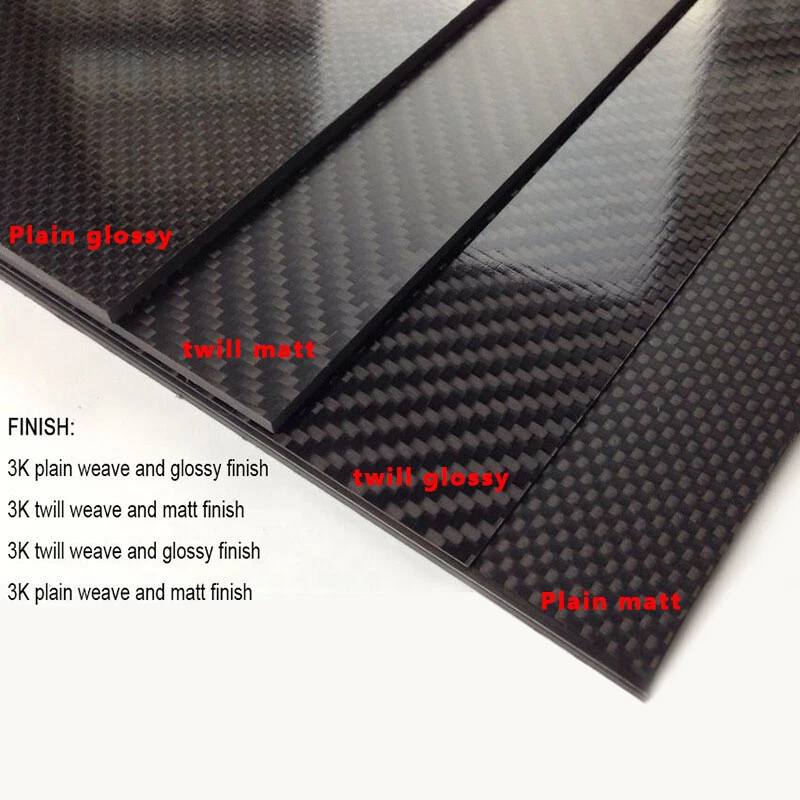

- Tecido liso: Simples sobre/sob. Boa estabilidade, propriedades equilibradas. Manuseamento mais fácil.

- Tecido de sarja (2×2, 4×4): Caimento mais suave, melhor conformabilidade do que o liso. Contornos complexos.

- Tecido de cetim (por exemplo, 5HS, 8HS): Excelente caimento, franzido reduzido. Moldes complexos, superfícies de alta qualidade.

- Tecido não engomado (NCF): Camadas cosidas de camadas UD ou tecidas. Desempenho mecânico superior.

- Pequeno reboque (1K-12K):

- Melhor caimento, acabamento da superfície. Formas complexas, artigos de desporto.

- Reboque grande (24K-50K+):

- Custo mais baixo por kg, taxas de deposição mais elevadas. Setor automóvel, industrial.

- Unidirecional (UD): Fibras todas em 0°. Resistência/rigidez máxima na direção primária. Laminados.

- Tecido liso: Simples sobre/sob. Boa estabilidade, propriedades equilibradas. Manuseamento mais fácil.

- Tecido de sarja (2×2, 4×4): Caimento mais suave, melhor conformabilidade do que o liso. Contornos complexos.

- Tecido de cetim (por exemplo, 5HS, 8HS): Excelente caimento, franzido reduzido. Moldes complexos, superfícies de alta qualidade.

- Tecido não engomado (NCF): Camadas cosidas de camadas UD ou tecidas. Desempenho mecânico superior.

algumas tranças comuns

Peso por unidade de área (g/m² ou oz/yd²). Afecta a espessura do laminado, o teor de resina e o tempo de processamento.

Assegurar a compatibilidade com o sistema de resina escolhido (epóxi, poliéster, éster de vinilo, bismaleimida, termoplástico).

Crítico para a adesão fibra-matriz (resistência de ligação). Especificar com base no tipo de resina.

- Tecido seco: Necessita de infusão de resina.

- Prepreg: Pré-impregnado com resina (armazenamento congelado). Qualidade consistente, colocação mais fácil.

- Fio/tapete cortado: Para compostos de moldagem, reforço de fibras curtas.

- Perfis pultrudidos: Secções transversais constantes (varas, tubos).

3. Recomendações baseadas em aplicações

- Aeroespacial (estruturas primárias): Fibras IM ou HM, pré-impregnados UD ou tecidos de camada fina, controlo de elevado teor de resina.

- Automóvel (Desempenho): Fibras SM ou IM, tecidos de grandes dimensões ou NCF, pré-impregnados de cura rápida/sistemas de resina.

- Artigos de desporto (bicicletas, raquetes): Fibras SM ou IM, sarja 3K para estética, UD para zonas de desempenho, pré-impregnado ou colocação húmida.

- Eletrónica de consumo: Fibras HM para rigidez, tramas finas ou UD para perfis elegantes, graus de proteção EMI.

- Industrial/Robótica: Fibras SM ou IM, Tecidos de grandes dimensões e económicos, Resinas epóxidas ou de éster vinílico.

- Marinha: Fibras SM, Tecidos (sarja/estanho), Viniléster ou epóxi para resistência à corrosão.

4. Considerações sobre fornecedores e qualidade

- Reputação do fornecedor: Certificações (AS9100, ISO 9001), património aeroespacial.

- Consistência: Variabilidade de lote para lote nas propriedades, tamanho, peso.

- Disponibilidade de dados: Acesso a dados certificados de propriedades mecânicas (tração, compressão, cisalhamento).

- Prazos de entrega e disponibilidade: Crítico para o planeamento do projeto.

5. Considerações sobre o processamento

- Estratificação manual (húmida): Escolher tecidos com bom caimento (sarja, cetim), peso areolar controlável.

- Infusão de resina (VARTM, RTM): Selecionar tecidos permeáveis/NCFs, meios de fluxo compatíveis.

- Pré-impregnação: Requer cura em autoclave/forno. Considerar a aderência, o tempo de vida útil e o ciclo de cura.

- Moldagem por compressão: Fibra cortada, SMC, ou tecidos pré-formados.

- Processos automatizados (ATL/AFP): fitas UD ou tecidos cortados. Controlo preciso da largura.

6. Otimização de custos

-

Avaliar: Tecido seco vs. pré-impregnado, módulo padrão vs. módulo elevado.

-

Minimizar o desperdício: Encaixe eficiente, métodos de corte optimizados.

-

Eficiência do processo: Resinas de cura mais rápida, técnicas de trabalho reduzidas (automatização, infusão).

7. Fluxograma de decisões-chave

- Definir os requisitos da aplicação: Cargas (tração, compressão, cisalhamento), rigidez, objectivos de peso, ambiente, factores de segurança.

- Identificar propriedades críticas: A força, a rigidez, a resistência ao impacto ou a vida à fadiga são fundamentais?

- Considerar o método de fabrico: Camada húmida, pré-impregnado, infusão, moldagem?

- Selecione o tipo de fibra e o tamanho do reboque: SM, IM, HM? 3K, 12K, 50K?

- Escolha a trama e o peso da área: UD, liso, sarja, cetim? Que g/m²?

- Especificar a compatibilidade da resina e a forma: Pré-impregnado ou tecido seco? Sistema de resina compatível.

- Avaliar fornecedores e custos: Equilíbrio entre desempenho, qualidade e orçamento.

- Protótipo e teste: Validar a seleção antes da produção em grande escala.

8. Notas importantes

- Consultar especialistas: Envolver cientistas de materiais ou engenheiros de compósitos numa fase inicial.

- Teste: As fichas de dados dos materiais são guias; efetuar testes específicos da aplicação.

- Considere todo o sistema: A fibra é apenas um componente. A resina, o núcleo (se for em sanduíche) e o processo de fabrico são igualmente críticos.

- Sustentabilidade: Explorar opções de fibra de carbono reciclada sempre que o desempenho o permita.

Ainda confuso? Contacte-nos aqui