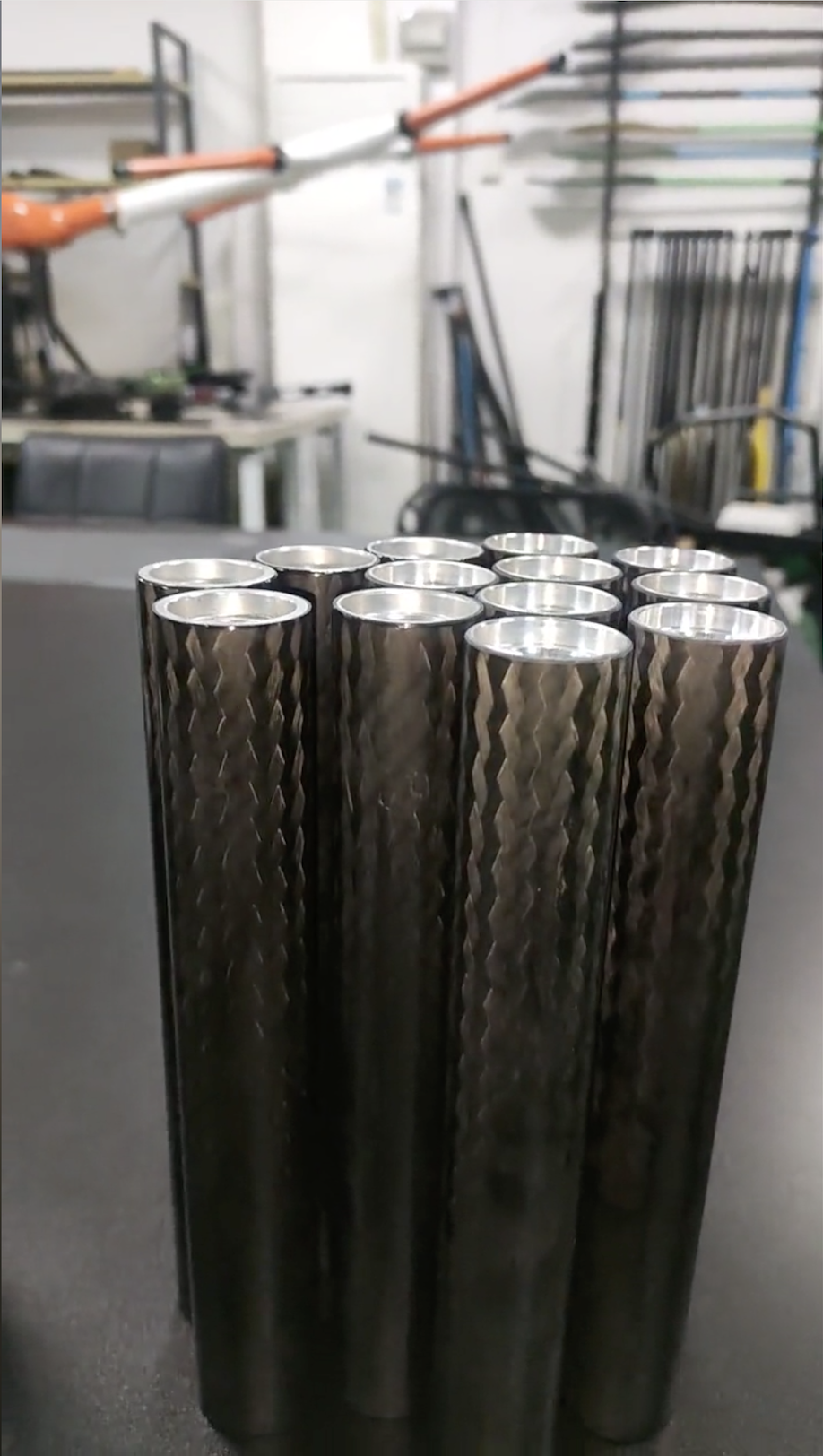

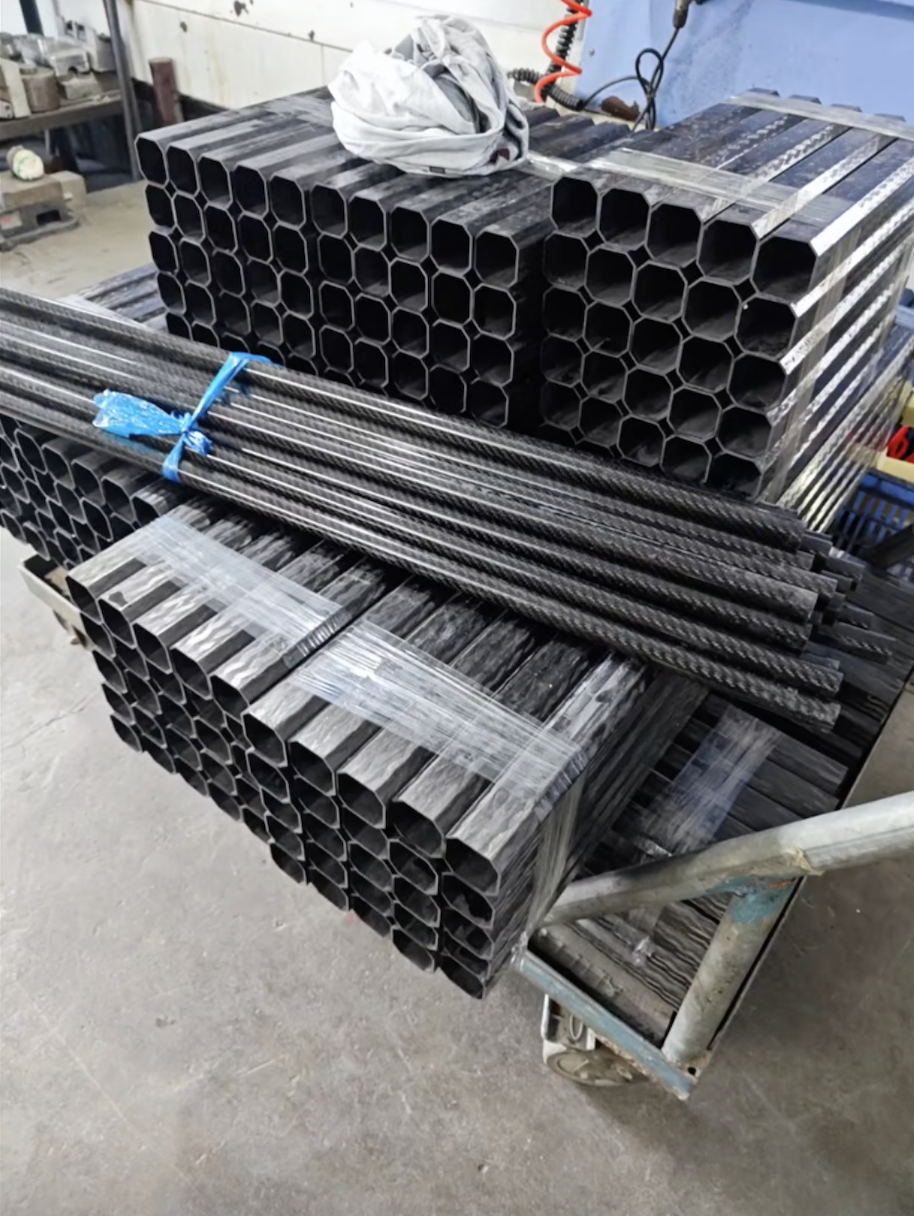

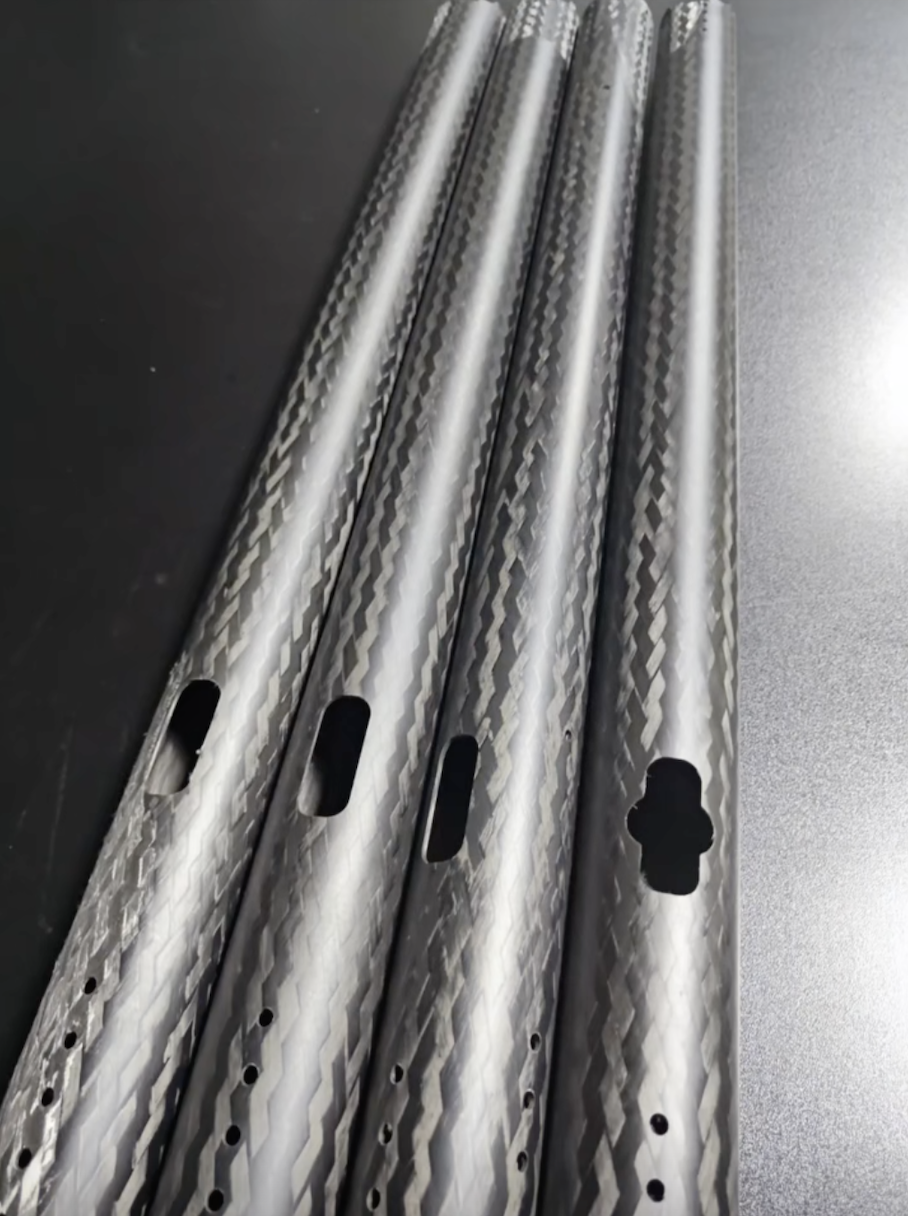

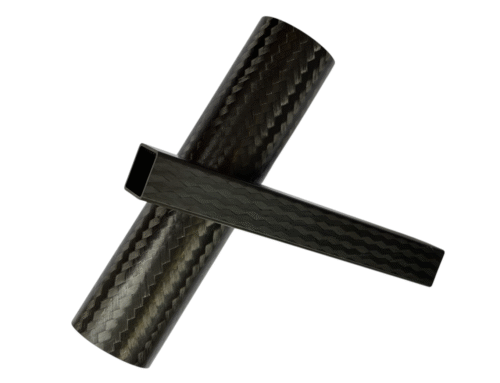

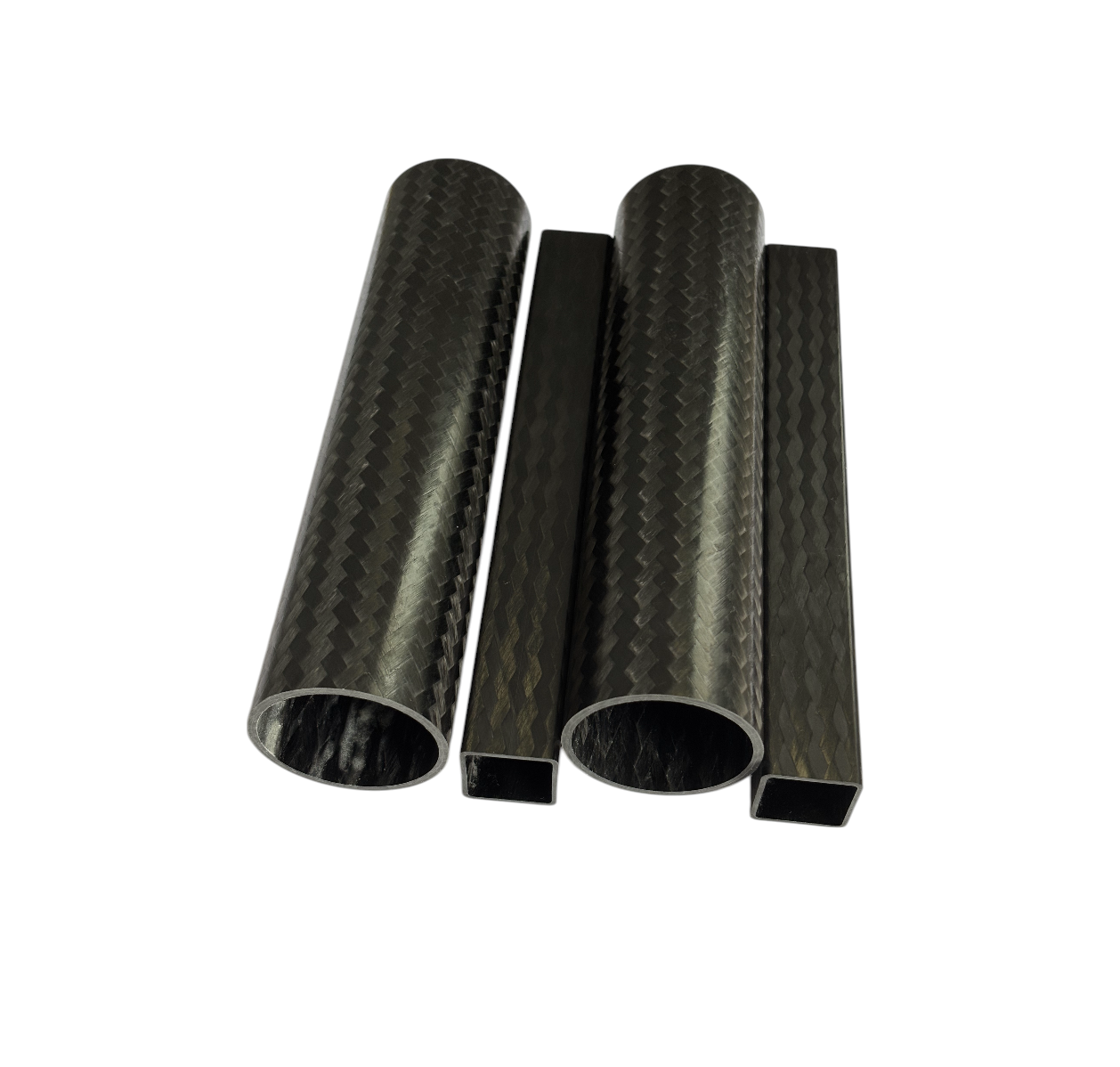

Tubos Pultrudidos Reforçados Trançados: Soluções superiores em fibra de carbono

Na E-YONNG Composites, tiramos partido da tecnologia de pultrusão de ponta para fabricar tubos pultrudidos reforçados com entrançados de qualidade superior - a solução definitiva para aplicações industriais exigentes. Como uma fábrica de fibra de carbono verticalmente integrada, controlamos todas as fases de produção, desde a fibra em bruto até ao tubo composto entrançado pultrudido acabado, garantindo uma consistência de qualidade inigualável.

Porquê escolher os nossos tubos de pultrusão entrançados?

- Produção interna de fibra de carbono para um controlo superior do material

- Fabrico com certificação ISO e precisão automatizada

- Otimização da arquitetura de fibra personalizada para requisitos de carga específicos

- Protocolos rigorosos de controlo de qualidade a nível aeroespacial

Vantagens críticas em relação aos tubos unidireccionais

Tubo de pultrusão entrançado oferece benefícios transformadores em comparação com as alternativas unidireccionais tradicionais:

Superioridade estrutural

-

Reforço de 360 de entrançados entrelaçados vs. apenas resistência linear

-

45% maior resistência ao impacto devido ao alinhamento multidirecional das fibras

-

Maior tolerância aos danos com resistência à propagação de fissuras

-

Rigidez torsional superior para aplicações rotativas

Benefícios de desempenho

-

20% melhor resistência à fadiga em ambientes de carga cíclica

-

Redução do risco de delaminação nos pontos de concentração de tensões

-

Estabilidade dimensional melhorada em ciclos térmicos

-

Maior resistência ao cisalhamento para cenários de carga complexos

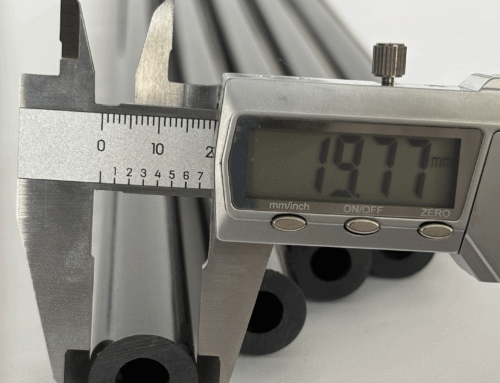

Tamanhos e especificações padrão

| Diâmetro exterior (mm) | Espessura da parede (mm) | Comprimentos comuns (m) |

|---|---|---|

| 5 – 25 | 1.0 – 2.5 | 0.2 – 5 |

| 26 – 50 | 2.0 – 4.0 | 0.2 – 5 |

| 51 – 100 | 3.0 – 8.0 | 0.2 – 5 |

| 101 – 200 | 5.0 – 15.0 | Personalizado |

Especificações da fibra de carbono

| Caraterísticas | T300 | T700 | T800 |

|---|---|---|---|

| Densidade (g/cm³) | 1.55 | 1.55 | 1.55 |

| Resistência à tração (MPa) | 3400 | 4900 | 5200 |

| Módulo de elasticidade (GPa) | 240 | 250 | 295 |

| Alongamento (%) | 1.78 | 1.76 | 1.7 |

Aplicações líderes na indústria

Os nossos tubos compósitos entrançados pultrudidos são excelentes em..:

- Braços robóticos que requerem uma otimização da rigidez em relação ao peso

- Equipamento de imagiologia médica que necessita de transparência EMI

- Actuadores aeroespaciais que exigem resistência à fadiga

- Isoladores de alta tensão que requerem resistência dieléctrica

- Equipamento desportivo de alto desempenho que procura amortecimento de vibrações