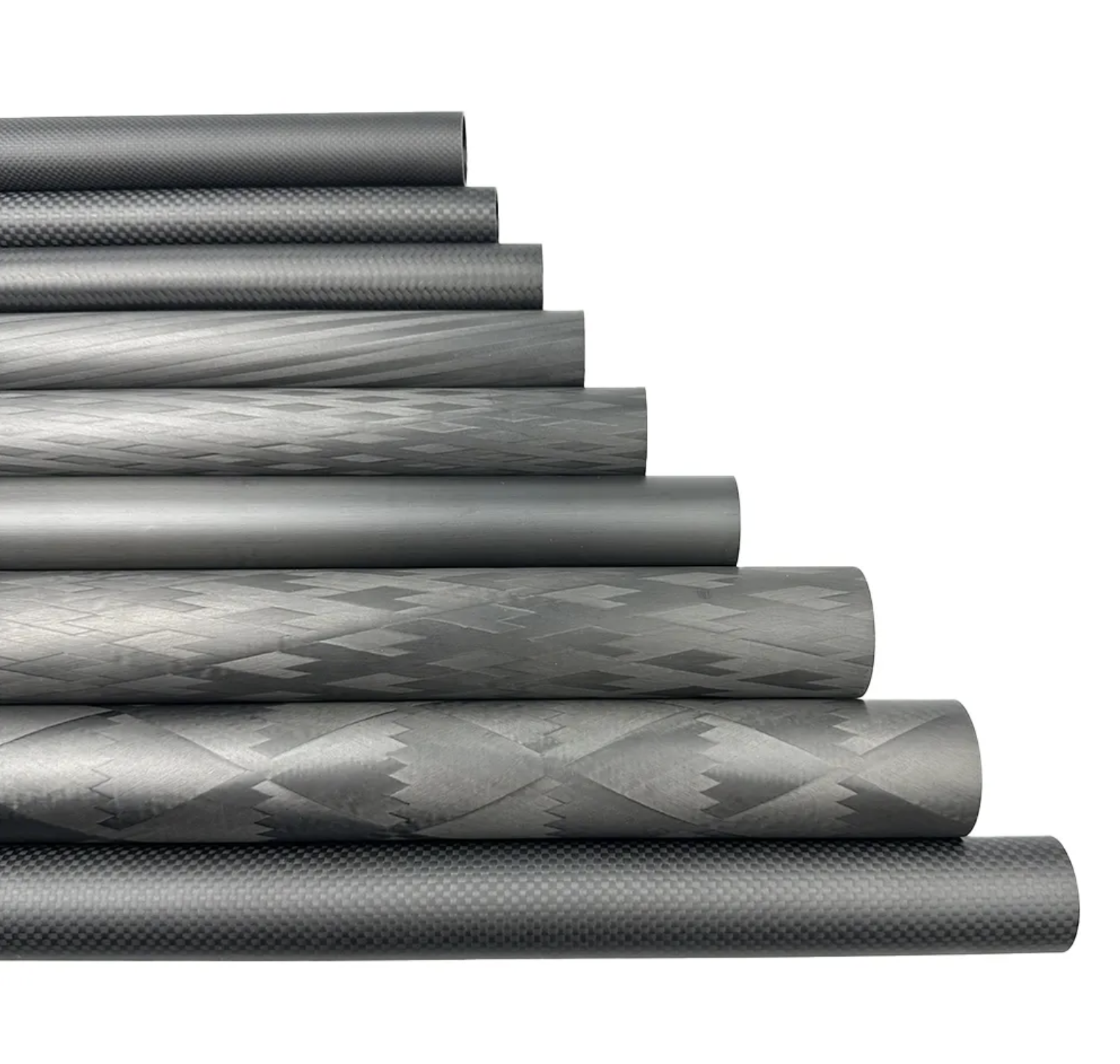

Custom Carbon Fiber Tube Manufacturing Service

We offer precision carbon fiber tube manufacturing based on customer-provided drawings. Our service is ideal for clients who already have specific designs and require high-quality, custom-made carbon fiber tubes. From aerospace to automotive, sports equipment, and industrial applications, we ensure your tubes are manufactured to exact specifications.

Key Features of Our Service:

Customer-Provided Designs: We work directly with your provided drawings or CAD files to manufacture carbon fiber tubes.

High Precision: Advanced manufacturing techniques ensure tight tolerances and consistent quality.

Material Options: A variety of carbon fiber grades and resin systems are available to meet your performance needs.

Surface Finish: Customizable finishes, including glossy, matte, or textured options.

Manufacturing Process:

Design Review

Our team reviews your provided drawings or CAD files to confirm manufacturability.

We discuss material options (carbon fiber type, resin, etc.) based on your application requirements.

Mold Preparation

A custom mold is created based on your design specifications.

The mold is precision-machined to ensure the final product matches your exact dimensions.

Layup Process

Carbon fiber sheets are cut and layered onto the mold according to your design.

Each layer is carefully oriented to achieve the desired strength and stiffness.

Resin Infusion & Curing

The carbon fiber layers are infused with resin using techniques like vacuum bagging or resin transfer molding (RTM) to ensure even distribution.

The assembly is cured in a controlled environment (oven or autoclave) for maximum strength.

Demolding & Trimming

Once cured, the carbon fiber tube is removed from the mold.

Excess material is trimmed, and the tube is inspected for quality.

Surface Finishing & Quality Control

The tube undergoes surface finishing (sanding, polishing, or coating) as per your requirements.

Rigorous quality control checks, including dimensional inspection and non-destructive testing (NDT), ensure the final product meets industry standards.

Packaging & Delivery

The finished tubes are carefully packaged to prevent damage during transit.

We ensure timely delivery to your specified location.

service related FAQ’s

We use carbon fibers from Toray. Toray’s T300, T700, and T800 carbon fibers represent a range of high-performance materials tailored for different needs. T300 is a cost-effective, general-purpose option, while T700 offers higher strength for more demanding applications. T800, with its ultra-high strength and modulus, is ideal for advanced aerospace and industrial uses. These carbon fibers are widely recognized for their reliability and versatility in various industries

| T300 | T700 | T800 | |

|---|---|---|---|

| Tensile Strength | 3,530 MPa | 4,900 MPa | 5,880 MPa |

| Tensile Modulus | 230 GPa | 230 GPa | 294 GPa |

| Elongation | 1.5% | 2.1% | 2.0% |

| Density | 1.76 g/cm³ | 1.80 g/cm³ | 1.81 g/cm³ |

| Applications | General-purpose | High-strength | Ultra-high performance |

Up to 1 meter

Here’s a detailed comparison between carbon fiber rolled tubes and filament-wound tubes in English, covering manufacturing processes, performance, applications, and more:

Manufacturing Process

| Aspect | Rolled Tubes | Filament-Wound Tubes |

|---|---|---|

| Core Process | Layered wrapping of prepreg or dry fabric around a mandrel, followed by curing. | Automated winding of resin-impregnated fibers onto a mandrel at controlled angles (e.g., 0°, ±45°, 90°), then cured. |

| Automation | Manual or semi-automated, simple setup. | Highly automated, requiring precision equipment for fiber tension and angle control. |

| Fiber Orientation | Limited to axial or hoop directions. | Multi-angle fiber alignment for optimized strength and stiffness. |

| Shape Flexibility | Best for simple cylindrical shapes. | Suitable for complex geometries (e.g., tapered, irregular cross-sections). |

Performance Comparison

| Property | Rolled Tubes | Filament-Wound Tubes |

|---|---|---|

| Mechanical Strength | High axial strength but weak hoop strength; prone to delamination. | Balanced axial/hoop strength; superior compressive/torsional resistance. |

| Anisotropy | Highly anisotropic (direction-dependent). | Reduced anisotropy via multi-angle layering. |

| Weight Efficiency | Moderate (uneven wall thickness). | Excellent (uniform fiber distribution, precise wall thickness control). |

| Fatigue Resistance | Lower (weak interlayer bonding). | High (continuous fibers, strong interlayer adhesion). |

Cost & Production

| Factor | Rolled Tubes | Filament-Wound Tubes |

|---|---|---|

| Equipment Cost | Low (simple tools or manual). | High (specialized winding machines, tension systems). |

| Production Cost | Low for small batches. | High initial cost, but cost-effective for large volumes. |

| Production Speed | Fast (simple curing process). | Slower (precision winding and curing). |

| Scalability | Limited to small-scale production. | Ideal for mass production. |

Applications

| Field | Rolled Tubes | Filament-Wound Tubes |

|---|---|---|

| Industrial | Decorative parts, lightweight frames, drone arms. | High-pressure tanks, pipelines, robotic arms. |

| Aerospace | Non-load-bearing components (e.g., interior brackets). | Rocket motor casings, aircraft landing gear. |

| Sports Equipment | Low-cost fishing rods, tent poles. | High-end bicycle frames, yacht masts. |

| Energy | — | Hydrogen storage tanks, wind turbine spar tubes. |

Selection Guide

- Choose Rolled Tubes:

- Budget constraints.

- Low-volume customization.

- Non-critical structural applications (e.g., aesthetics, lightweight frames).

- Choose Filament-Wound Tubes:

- High-performance load-bearing applications.

- Complex fiber orientation requirements.

- Mass production with strict quality control.

Up to 230°C (446°F)