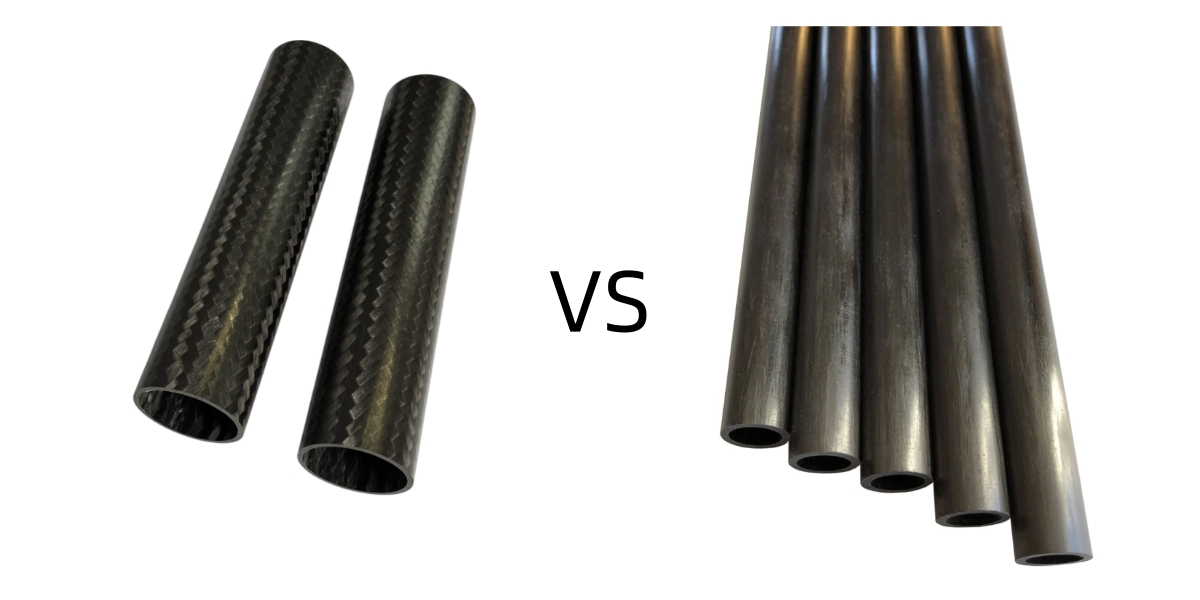

När ingenjörer väljer kolfiberrör för högpresterande applikationer står de inför ett kritiskt val mellan flätade och enkelriktade pultruderade konstruktioner. Denna omfattande jämförelse undersöker deras strukturella egenskaper, tillverkningsprocesser och idealiska användningsfall för att hjälpa dig att fatta ett välgrundat beslut.

VANLIGA FRÅGOR

F: Kan flätade rör matcha enkelriktad axiell hållfasthet?

S: De uppnår 85-90% av ren axiell styrka samtidigt som de tillför multidirektionella egenskaper.

F: Vilken typ är bäst för vibrationstillämpningar?

A: Flätade rör är betydligt bättre än enkelriktade när det gäller att dämpa vibrationer.

F: Går det att spara vikt med enkelriktade rör?

S: Ja, de är normalt 5-8% lättare än motsvarande flätade slangar.

F: När är det enkelriktade rörets kostnadsfördel avgörande?

A: Vid högvolymproduktion där endast axiell hållfasthet krävs.

Valet mellan flätade och enkelriktade pultruderade kolfiberrör beror i slutändan på dina specifika prestandakrav och budgetbegränsningar. Medan enkelriktade rör erbjuder maximal axiell hållfasthet till lägre kostnad, ger flätade rör omfattande strukturella prestanda för krävande applikationer. Utvärdera dina belastningsförhållanden, miljöfaktorer och prestandabehov för att välja den optimala lösningen.