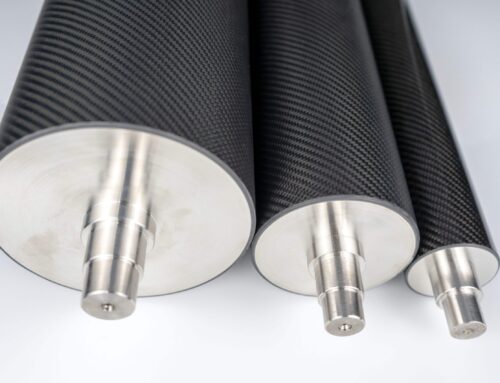

At E-YOUNG Composites, we specialize in advanced composite solutions, and one of our most sought-after products is the pull-wound carbon fiber tube. Renowned for its exceptional strength-to-weight ratio, dimensional precision, and cost-effectiveness, this manufacturing process creates tubing ideal for a wide range of demanding applications.

But what exactly is pull-wound tubing, and why might it be the perfect choice for your project? This comprehensive guide will delve into everything you need to know.

What is Pull-Wound Carbon Fiber Tube?

Pull-wound, also known as pultrusion-winding or pull-winding, is a continuous, automated manufacturing process that combines the principles of pultrusion och lindning av filament.

Here’s a simplified breakdown of the process:

-

Fibers: Continuous carbon fiber tows (or a hybrid with fiberglass) are fed through a resin bath, becoming fully impregnated.

-

Forming & Winding: The wet fibers are pulled through a heated die to form the basic tube shape. Simultaneously, additional fiber tows are wound at specific angles around the tube as it is being pulled.

-

Curing: The combination of heat from the die and the tension from the pulling and winding actions cures the resin into a rigid, solid composite.

-

Cutting: The continuous, cured tube is automatically cut to the desired lengths.

This hybrid method results in a product that leverages the best of both worlds: the consistent cross-section and high axial strength of pultrusion, combined with the enhanced hoop strength and torsional rigidity from the winding process.

Key Advantages of Pull-Wound Carbon Fiber Tubes

Why choose pull-wound tubes over other types like roll-wrapped or filament-wound?

-

Superior Strength & Stiffness: The unidirectional fibers from the pultrusion process provide excellent tensile and flexural strength along the tube’s length, while the wound fibers add burst pressure resistance and improved torque performance.

-

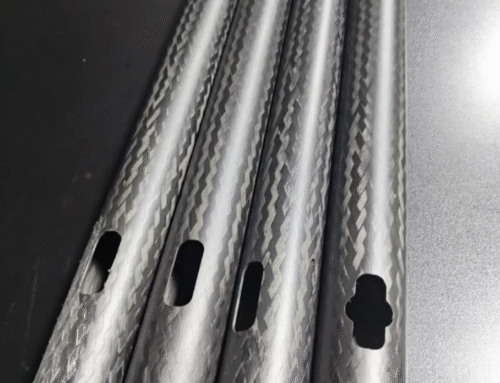

Excellent Surface Finish: Tubes produced with the pull-wound method typically have a very smooth, consistent outer surface, often superior to pure filament-wound tubes, which reduces drag and improves aesthetics.

-

High Dimensional Accuracy & Consistency: As an automated process, pull-winding produces tubes with extremely tight tolerances on both inner diameter (ID) and outer diameter (OD). This is critical for applications involving precise fittings and assemblies.

-

Outstanding Cost-Effectiveness: It’s a high-volume, continuous process with minimal manual labor, leading to a lower cost per meter compared to many other composite tube manufacturing methods. This makes high performance more accessible.

-

Flexibilitet i utformningen: We at E-YOUNG can customize the fiber orientation (e.g., the angle of the wind) and the carbon/fiberglass hybrid ratio to tailor the mechanical properties for your specific load requirements.

Pull-Wound vs. Other Manufacturing Methods

| Funktion | Pull-Wound | Roll-Wrapped | Filament-Wound |

|---|---|---|---|

| Axiell styrka | Very High | Bra | Måttlig |

| Hoop Strength | High | Måttlig | Very High |

| Ytfinish | Very Smooth | Smidig | Textured (Helical Pattern) |

| Dimensional Consistency | Utmärkt | Bra | Bra |

| Production Speed/Cost | High / Low Cost | Medium / Medium Cost | Medium / Medium Cost |

Common Applications of Pull-Wound Carbon Fiber Tubes

The unique properties of pull-wound tubes make them suitable for numerous industries:

-

Industriell automation: Robot arms, gantries, and conveyor system components where stiffness and low weight are critical for speed and precision.

-

Flyg- och rymdfart samt UAV: Drone booms, structural frames, and antenna masts requiring a perfect balance of strength, weight, and durability.

-

Medical & Rehabilitation: Lightweight components for medical devices, prosthetics, and orthotics where patient comfort and device performance are paramount.

-

Sports & Recreation: Tent poles, kite spars, fishing rods, and high-performance bicycle components.

-

Optics & Telescopes: Truss systems for telescopes where thermal stability and minimal deformation are essential.

Why Choose E-YOUNG Composites for Your Pull-Wound Tubes?

As a leading manufacturer of carbon fiber and fiberglass composites, E-YOUNG Composites is your trusted partner for high-quality pull-wound tubing.

-

Expert Engineering Support: We help you select the right specifications, including diameter, wall thickness, fiber orientation, and resin system.

-

Full Customization: We produce tubes to your exact requirements, from standard round tubes to custom shapes and hybrid constructions.

-

Rigorös kvalitetskontroll: Every batch of tubes undergoes strict inspection to ensure it meets our high standards for mechanical properties and dimensional accuracy.

-

Global Logistics: We reliably serve clients worldwide with efficient shipping and logistics.

Ready to experience the E-YOUNG difference?

Do you have a project that could benefit from the lightweight strength and precision of pull-wound carbon fiber tubes?

Contact Us Today for a Free Quote! Let our experts provide you with a competitive price and technical data sheet.

You can also reach us directly at info@carbonfibercfk.com.